Making World-class Technology Affordable

Industry Leading 25+ Years

Transforming Tomorrow

Comprehensive Solutions

Igniting

Excellence

For over 25 years, S&T Engineers (P) Ltd. has been a leading provider of top-notch metal cutting, EDM solutions, machine tool accessories, and consumables. As leading machine tool and accessories distributors in India, we have evolved from a small firm to a significant multi-location leader. We have partnered with world-class brands like Makino, YCM, Manford, Excetek, Bedra, Pratic, WIM, Vertex, Kelch, and MPA to serve a wide range of manufacturing industries. Our commitment to quality, value, and comprehensive pan-India support ensures we meet the needs of both small businesses and large corporations efficiently

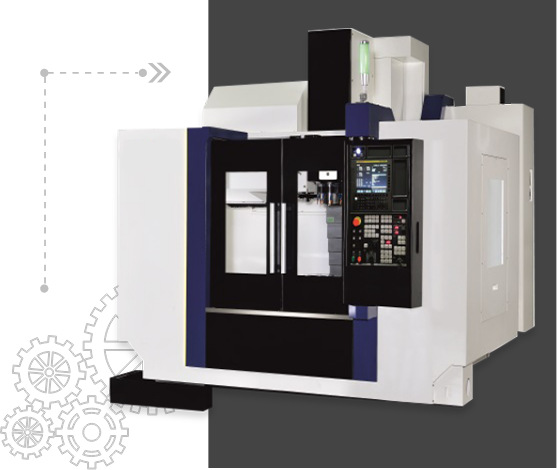

Metal Cutting Machine

Metal Cutting Machine

At S&T Engineers, we are at the forefront of providing affordable, technology-driven metal-cutting CNC machines, establishing ourselves as premier metal cutting CNC machine suppliers in India. Our products embody world-class engineering and innovation, making us a key resource for CNC machines for the manufacturing industry. Partnering with internationally acclaimed brands like YCM and Makino, we deliver an extensive lineup of machining solutions tailored to the dynamic needs of industries.

Our selection features cutting-edge Machining Centers, including versatile 3-axis and 5-axis VMCs, Long-travel Machining Centers for extensive projects, Double-column Machining Centers for increased stability and precision, and high-performance Turning Centers. These machines are designed to boost productivity and precision in a range of sectors:

![]() Aerospace

Aerospace

![]() Automotive

Automotive

![]() Medical

Medical

![]() Electronics

Electronics

![]() Jewellery

Jewellery

Get Info

Get Info

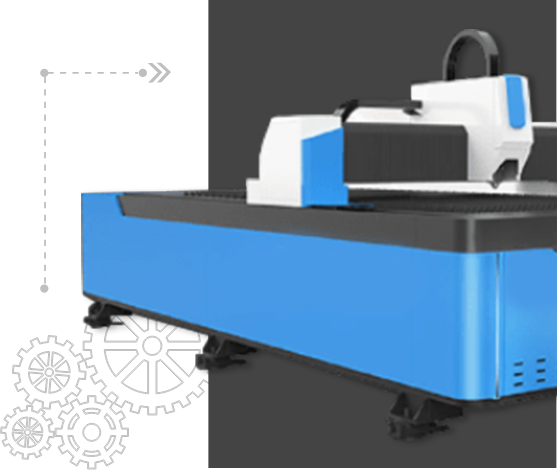

Metal Forming Machine

Metal Forming Machine

S&T Engineers are the premier suppliers of metal forming machines, partnering with world-renowned brands SENFENG and DENER MAKINA to bring affordable, technologically advanced solutions to the Indian engineering industry. Our extensive selection encompasses everything from sheet metal and tube laser cutting machines to hydraulic press brakes, shearing machines, all-electric sheet metal press brakes, and laser welding machines, all embodying the pinnacle of world-class innovation.

![]() Notable Milestone: Achieving over 100 SENFENG installations within a single year.

Notable Milestone: Achieving over 100 SENFENG installations within a single year.

![]() Unrivaled Quality: Our dedication to offering the best-in-quality metal-forming machines sets us apart, ensuring our clients receive products that lead the market in innovation and reliability.

Unrivaled Quality: Our dedication to offering the best-in-quality metal-forming machines sets us apart, ensuring our clients receive products that lead the market in innovation and reliability.

Get Info

Get Info

EDM Machines

EDM Machines

S&T Engineers stands as the preeminent supplier of Wire and Die Sinking EDM Machines, featuring the globally acclaimed EXCETEK brand. As the exclusive co-manufacturing venture for EXCETEK EDM Machines in India, we bring together affordable engineering solutions with world-class technology and innovation. Our S&T EXCETEK machines set the standard for accuracy, surface finish, and quality, ensuring unparalleled precision in every task.

Our EDM machines are versatile and find applications across various sectors, enhancing efficiency and precision in:

![]() Job Work

Job Work

![]() Tool Room

Tool Room

![]() Dies & Moulds

Dies & Moulds

![]() Automotive

Automotive

![]() Oil & Gas

Oil & Gas

![]() Aerospace

Aerospace

Get Info

Get Info

Conventional Machines

Conventional Machines

S&T Engineers stands at the forefront of supplying Manford Milling Machines in India, showcasing a blend of affordable engineering, world-class technology, and innovation. As renowned DRO Milling machine distributors, our extensive product lineup, including Surface Grinding, Universal Milling, Radial Drilling, Manual Lathe, Band Saw, and Tapping Machines, is crafted to meet the diverse needs of the engineering industry with precision and durability.

![]() With over 17,000 milling machine installations, our expertise and reliability are unmatched.

With over 17,000 milling machine installations, our expertise and reliability are unmatched.

![]() Our wide selection of machines ensures you find the exact equipment to meet your specific needs.

Our wide selection of machines ensures you find the exact equipment to meet your specific needs.

![]() Each machine is built to last, embodying high-quality engineering for sustained performance.

Each machine is built to last, embodying high-quality engineering for sustained performance.

![]() We're not just about sales; our excellent customer service ensures your satisfaction and success.

We're not just about sales; our excellent customer service ensures your satisfaction and success.

Get Info

Get Info

Machine Tool Accessories

Machine Tool Accessories

For more than 25 years, S&T Engineers has been at the pinnacle of supplying machine tool spares and accessories, partnering with the esteemed Taiwanese brand VERTEX to deliver affordable, technology-driven solutions. Our commitment to world-class engineering and innovation is evident in our comprehensive one-stop solution for all spare and accessory needs.

![]() One-Stop Solution: Simplify your procurement process with our extensive selection of machine tool spares and accessories.

One-Stop Solution: Simplify your procurement process with our extensive selection of machine tool spares and accessories.

![]() Extensive Product Range: Our wide range of products ensures you find exactly what you need for your operations.

Extensive Product Range: Our wide range of products ensures you find exactly what you need for your operations.

![]() Nationwide Sales: Our reach extends across India, ensuring that our machine tool spares and accessories are accessible to every corner of the country.

Nationwide Sales: Our reach extends across India, ensuring that our machine tool spares and accessories are accessible to every corner of the country.

Get Info

Get Info

Plastic Injection Moulding Machine

Plastic Injection Moulding Machine

S&T Engineers is your go-to source for Tederic and Denice plastic injection moulding machines, known for their durability and quality. As exclusive distributors, we offer machines with 80–4000 tonnage capacity, catering to a broad range of production needs in the plastics industry worldwide.

![]() Our machines are engineered to last, ensuring continuous, reliable performance.

Our machines are engineered to last, ensuring continuous, reliable performance.

![]() We provide excellent customer service, supporting your operations every step of the way.

We provide excellent customer service, supporting your operations every step of the way.

![]() From small to large-scale production, our machines offer the versatility your projects demand.

From small to large-scale production, our machines offer the versatility your projects demand.

Get Info

Get Info

Industry Leading

25+ Years

Transforming Tomorrow

Comprehensive Solutions

Igniting

Excellence

S&T Engineers (P) Ltd is one of the most trusted and reliable manufacturers & suppliers in the Machine Tool industry.

S&T has a global infrastructure & presence with a manufacturing base in Coimbatore and a strong sales & service force across India.

With our extensive sales and service network across India, we ensure maximum uptime for your machine tools, empowering your operations with expert support and efficiency.

We view our relationship with you as a partnership, where your success stories become our shared victories. Together, we strive for excellence in machine tool applications.

Bridging international borders, we bring global manufacturing trends right to your doorstep, helping you shape a future that keeps you ahead in the competitive manufacturing arena.

S&T Engineers is committed to bringing the latest advancements in machine tool technology directly to you. We actively participate in nationwide industry events, exhibitions, and seminars, providing a platform to connect with our customers and showcase our comprehensive range of international brand machines and cutting-edge solutions.

But that's not all! S&T Engineers fosters a vibrant work culture that fuels innovation and excellence. Join us as we explore upcoming industry events and get a glimpse into the exciting world of S&T Engineers!