NXV1680B

YCM CNC Vertical Machining Center NXV1680B

S&T Engineers Is The Authorised Distributors Of YCM VMC Machines In India. YCM High Precision And Reliable NXV Series VMC Specially Crafted For High Productivity Applications. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 6,000(10,000) Spindle Taper (Opt.) - BT50 ( BBT50)

Travel

Travel(mm)(X-Y-Z) - 1630-860-762

ATC

Tool Magazine Capacity (Opt.)(T) - 32(24 / 40)

SPECIFICATION

NXV1680B

Unit

Values

Spindle Speed (Opt.)

Rpm

6,000(10,000)

Spindle Power (Opt.)

KW

18.5(45)

Spindle Taper (Opt.)

BT50 ( BBT50)

X-Axis Travel

Mm

1630

Y-Axis Travel

Mm

860

Z-Axis Travel

Mm

762

Distance Between Spindle Nose & Table Top

Mm

200~962

Table Size

Mm

1,730 X 860

No. T-Slot X Size X Pitch

5 X 22 X 150

Max. Load On Table

Kg

2000

X/Y/Z Rapid Feedrate

M/min.

24/24/24

Cutting Feedrate

Mm/min.

1~10,000

Tool Magazine Capacity (Opt.)

T

32(24 / 40)

Tool Weight

Kg/pc

20

Max. Tool Dimension (W/O Adjacent Tools)

Mm

24T : ø110x 350 (ø190 X 350) 32T / 40T:ø120 X 350 (ø240 X 350)

Machine Weight

Kg

16500

YCM In-house IDD Spindle

- Standard gearhead spindle of maximum of 6,000 rpm high-speed with the maximum of 18.5 kW 25 HP power output and 48 kgf-m 347.19 lb-ft torque.

- Spindle speed of up to 10,000 rpm with IDD (Isolated Direct Drive) design, coupled with oil lubrication that can lower heat deviation, improve spindle accuracy and extend bearing life. Spindle power 22 kW 30 HP without gearbox, electric speed shift with spindle motor, maximum torque of 36 kgf-m 260.39 lb-ft. (option).

- The quill type spindle housing is with cooling system to assure the best temperature control of the spindle head, and for the best machining results.

- Deployed with precise angular contact ceramic ball bearings for extra axial and radial rigidity to fit the requirements of heavy cutting.

YCM In-house IDD Spindle

- Standard gearhead spindle of maximum of 6,000 rpm high-speed with the maximum of 18.5 kW 25 HP power output and 48 kgf-m 347.19 lb-ft torque.

- Spindle speed of up to 10,000 rpm with IDD (Isolated Direct Drive) design, coupled with oil lubrication that can lower heat deviation, improve spindle accuracy and extend bearing life. Spindle power 22 kW 30 HP without gearbox, electric speed shift with spindle motor, maximum torque of 36 kgf-m 260.39 lb-ft. (option).

- The quill type spindle housing is with cooling system to assure the best temperature control of the spindle head, and for the best machining results.

- Deployed with precise angular contact ceramic ball bearings for extra axial and radial rigidity to fit the requirements of heavy cutting.

High Rigidity Design

- FEM analysis is adopted to ensure the best mass arrangement and rib construction of the machine for constant stability under the intensive load of heavy-duty cutting.

- All axial AC servo motors equipped with Absolute Positioning Encoders, no zero return needed

- Direct drive provides backlash free, best accuracy, reliability and stability.

- High rigidity and high loading linear guideways applied on the three axes.

- 6 slide blocks on X-axis and 4 linear guideways on Y-axis

- No counter weight on Z-axis

- The rigid body construction makes for uncompromising precision and rigidity.

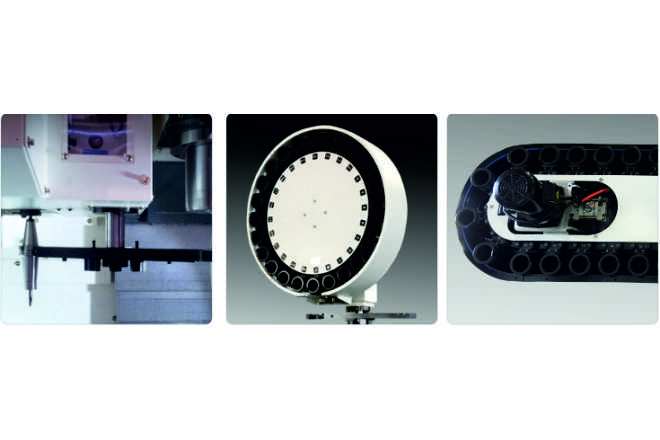

High Stability Tool Magazine

- Auto Tool Change (T-T): 4.2 sec.

- Tool Magazine Capacity: 32T (24T/40T opt.)

High Stability Tool Magazine

- Auto Tool Change (T-T): 4.2 sec.

- Tool Magazine Capacity: 32T (24T/40T opt.)

Automatic Tool Magazine Door Design

- Driven by pneumatic cylinder.

- Prevent coolant and chips from entering tool magazine.

Brand New Exterior Design

- Full enclosure exterior (including top cover).

- Convertible side window for convenient chip removal.

- Aesthetic rear cover design.

- Smooth chip removal.

- Quad chip augers (4 Y-axial) system ensures fluent chip removal prevent chips from piling up. [with Rear Side Chip Conveyor (opt.)]

Brand New Exterior Design

- Full enclosure exterior (including top cover).

- Convertible side window for convenient chip removal.

- Aesthetic rear cover design.

- Smooth chip removal.

- Quad chip augers (4 Y-axial) system ensures fluent chip removal prevent chips from piling up. [with Rear Side Chip Conveyor (opt.)]