H500B

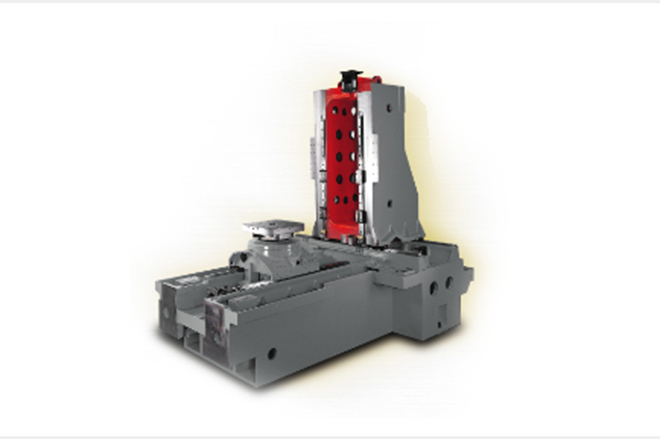

YCM CNC Horizontal Machining Center H500B

YCM CNC Horizontal Machining Center H500B Machines Are World Class Machines Well Known For Excelent Precision And Reliability. Over 70 Years Of YCM CNCs Sophisitcated Manufacturing Facility Has Led The Machines To Be Of Top Valued Cnc Machines In The World.

Travel

Travel - X/Y/Z - 700/650/650

Spindle

Spindle - 6000(10000) 22kW, BBT50

Table

Table - 500x500, Max Load - 500kg, APC Time - 10sec

SPECIFICATION

H500B

Unit

Values

Spindle Speed (Opt.)

Rpm

6,000 (10,000)

Spindle Power (Opt.)

KW

22

Spindle Taper (Opt.)

-

BBT50

X-Axis Travel

Mm

700

Y-Axis Travel

Mm

650

Z-Axis Travel

Mm

650

Distance Between Spindle Center And Table Top

Mm

50~700

Distance Between Spindle Nose And Table Center

Mm

150~800

Table Size

Mm

500 X 500

Max. Load On Table

Kg

600

Max. Work Dimensions

Mm

ø800 X 760

Height From Table Top To Floor

Mm

1250

Table Indexing Angle (Opt.)

-

1° (5°~ 0.001°)

APC Time

Sec

10

X/Y/Z Rapid Feedrate

M/min

40/40/40

Cutting Feedrate

Mm/min

1~20,000

Tool Magazine Capacity (Opt.)

T

40 (60/80)

Tool Weight

Kg/pc

20

Max. Tool Dimension (W/O Adjacent Tools)

Mm

ø125 X 400 (ø240 X 400)

Machine Weight

Kg

17,650

High Rigidity Construction With High Feedrate

- The moving column design, the strengthened 3-point support base, and dual wall rib-structure designed column sustain the utmost rigidity, accuracy level, and machine durability.

- Direct transmission design on all 3 Axes and pre-tensioned ballscrews ensure motion rigidity, and machining accuracy.

- Deploy high precision linear motion guideways, ensure excellent machining performance and service life with low friction, high rigidity, high speed and optimal damping force. The rapid feedrate is 40 m/min. (X/Y/Z), and 20 m/min. for max. cutting feedrate.

High Rigidity Construction With High Feedrate

- The moving column design, the strengthened 3-point support base, and dual wall rib-structure designed column sustain the utmost rigidity, accuracy level, and machine durability.

- Direct transmission design on all 3 Axes and pre-tensioned ballscrews ensure motion rigidity, and machining accuracy.

- Deploy high precision linear motion guideways, ensure excellent machining performance and service life with low friction, high rigidity, high speed and optimal damping force. The rapid feedrate is 40 m/min. (X/Y/Z), and 20 m/min. for max. cutting feedrate.

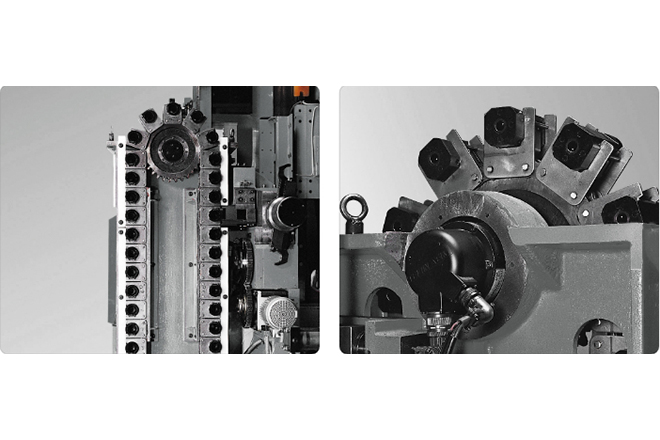

Quick and Reliable ATC Mechanism

- The roller-gear-cam ATC arm, parallel to the spindle of the short-pitch design, makes the ATC prompt and reliable; it takes only 2.9 sec.

- The magazine is precisely indexed and driven by servo motor for efficient operations.

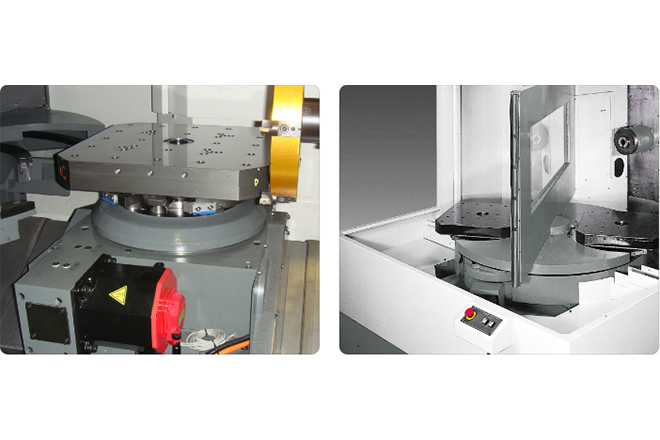

High precision, power clamp APC enhances flexibility and efficiency

- Compact and smart rotary pallet change design with unique and strengthen rail way support ensures the accurate, fast, and reliable APC.

- Pallet is swift (on Z-axis) to make APC, the rotary door is quickly turned along with APC, which takes only 10 sec.

- Large size ø450 mm ø17.72" position clutch is deployed, together with taper pin in precise positioning, strongly supports the table and meets the rigid machining needs.

- Optional 0.001° continuous feed 4th axis pallet of dual warm gear design is backlash-free and easily maintained.

High precision, power clamp APC enhances flexibility and efficiency

- Compact and smart rotary pallet change design with unique and strengthen rail way support ensures the accurate, fast, and reliable APC.

- Pallet is swift (on Z-axis) to make APC, the rotary door is quickly turned along with APC, which takes only 10 sec.

- Large size ø450 mm ø17.72" position clutch is deployed, together with taper pin in precise positioning, strongly supports the table and meets the rigid machining needs.

- Optional 0.001° continuous feed 4th axis pallet of dual warm gear design is backlash-free and easily maintained.