DV60T

YCM CNC Vertical Machining Center DV60T

S&T Engineers Is The Authorised Distributors Of YCM VMC Machines In India. YCM High Precision And Reliable DV Series Dual Spindle Compact VMC Machines Well Suited For High Productive Application. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 20,000(20,000/30,000)Spindle Taper (Opt.) - BT30 (BT30 / BBT30)

Travel

Travel(mm)(X-Y-Z) - 600-350-320

ATC

Tool Magazine Capacity (Opt.)(T) - 16(20)

SPECIFICATION

DV60T

Unit

Values

Spindle Speed (Opt.)

Rpm

20,000(20,000/30,000)

Spindle Power (Opt.)

KW

9(9/7.5)

Spindle Taper (Opt.)

BT30 (BT30 / BBT30)

X-Axis Travel

Mm

600

Y-Axis Travel

Mm

350

Z-Axis Travel

Mm

320

Distance Between Spindle Nose & Table Top

Mm

280~600

Table Size

Mm

1,300 X 400

No. T-Slot X Size X Pitch

Mm

3 X 14 X 100

Max. Load On Table

Kg

250

X/Y/Z Rapid Feedrate

M/min.

48/48/48

Cutting Feedrate

Mm/min.

1~20,000

Tool Magazine Capacity (Opt.)

T

16(20)

Tool Weight

Kg/pc

3

Max. Tool Dimension (W/O Adjacent Tools)

Mm

ø40 X 120

Machine Weight

Kg

4000

Highly Increase Production Capacity, Tremendously Reduces Cost

- High precision, high production with minimum floor space realizes tremendous cost-down.

- With more than 60% production capacity compared to tapping machine with the same size.

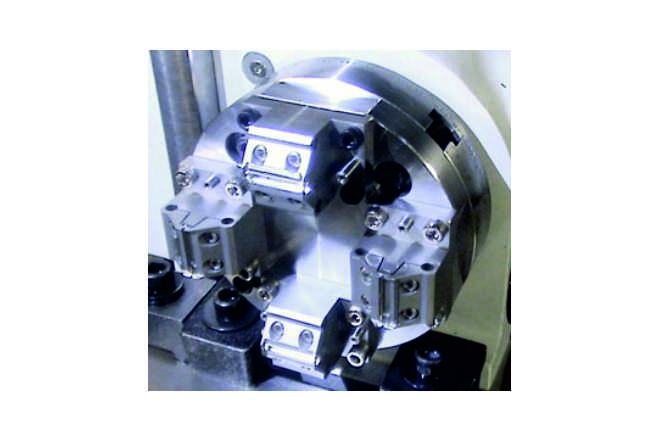

- Optional rotary table for multi-face milling, drilling, and tapping Works

Highly Increase Production Capacity, Tremendously Reduces Cost

- High precision, high production with minimum floor space realizes tremendous cost-down.

- With more than 60% production capacity compared to tapping machine with the same size.

- Optional rotary table for multi-face milling, drilling, and tapping Works

Efficient Chips Removal Design

- Slanted bed structure design speeds the chip and coolant removal, preventing chips from accumulating inside of the machine.

- Wide chip tank design can increase the chip removal capacity.