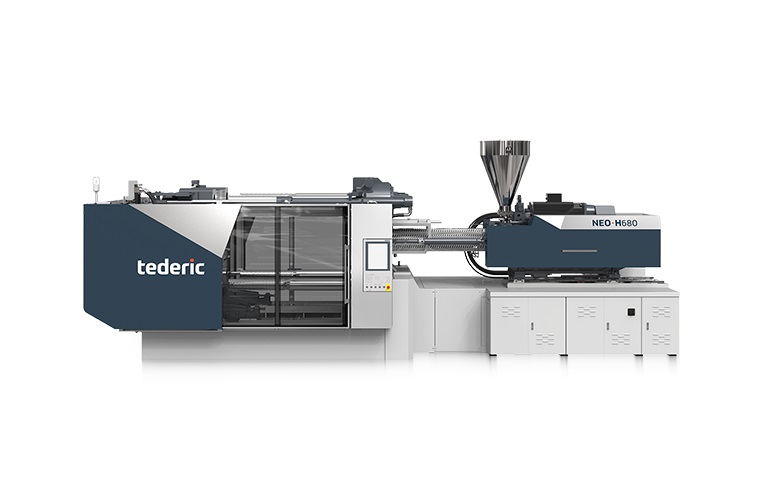

Tederic NEO H

NEO H Series Two Platen Injection Moulding Machine

S&T Engineers Is The Authorised Distributor Of The Tederic NEO H Two Platen Plastic Injection Molding Machine In India. The NEO H Series Is A Collection Of Innovative Patented Technologies With Flexible And Rich Functional Configurations To Provide You With Professional Customized Solutions.

Clamping Force

550T-4500T

Clamping Type

Two Platen

Power

Hydraulic System

SPECIFICATION

Tederic NEO H

Unit

Values

Minimum Tonnage

Tonnage

550T

Maximum Tonnage

Tonnage

4500T

Clamping Type

Two Platen

Power System

Hydraulic/Electric

Hydraulic

- Machines for a Wide Range of Applications: Daily Essentials, Home Appliances, Medical, Logistics, Construction

- The energy-saving effect is superior.

- Injection weight repeatability ≤0.3%; The repeat accuracy of mold opening position is≤1mm.

- Huge mold space, Modular design of mold opening cylinder.

- Machines for a Wide Range of Applications: Daily Essentials, Home Appliances, Medical, Logistics, Construction

- The energy-saving effect is superior.

- Injection weight repeatability ≤0.3%; The repeat accuracy of mold opening position is≤1mm.

- Huge mold space, Modular design of mold opening cylinder.

Clamping Unit

- Huge mold space, clamping stroke can be expanded

- Mould open position repeat accuracy ≤1mm

- Modular design of mold opening cylinder

- Increased mold support weight by 15% Tie-bar load eccentric ≤4%

- Stable synchronous lock structure: Lock cylinder with buffer unit. Accurate alignment without impact, stable tie bar position with even force.

- Huge mold space and opening stroke: Flexible for more molds. The exclusive mold protection function of the two-platen machine is safe and reliable.

- Pullsure™ technology (option): Solves customer factory height limits, improves mold change efficiency

- Short stroke clamping cylinder: Boosting stroke can speed up clamping force built, so mold force can be more even.

- Sliding foot oblique iron type support device: Can support heavier molds, mold Support weight increased by 15%

- High repeatability: Mold opening and closing controller by proportional valve, improve mold opening position and repeat the position accuracy, the repeat accuracy is within ±0.5mm

- Diagonal parallel cylinder structure: High speed cylinder with Diagonal parallel structure, guarantees stable and fast mold clamping & opening, shortens dry cycle time

- Stable synchronous lock structure: Lock cylinder with buffer unit. Accurate alignment without impact, stable tie bar position with even force.

- Huge mold space and opening stroke: Flexible for more molds. The exclusive mold protection function of the two-platen machine is safe and reliable.

- Pullsure™ technology (option): Solves customer factory height limits, improves mold change efficiency

- Short stroke clamping cylinder: Boosting stroke can speed up clamping force built, so mold force can be more even.

- Sliding foot oblique iron type support device: Can support heavier molds, mold Support weight increased by 15%

- High repeatability: Mold opening and closing controller by proportional valve, improve mold opening position and repeat the position accuracy, the repeat accuracy is within ±0.5mm

- Diagonal parallel cylinder structure: High speed cylinder with Diagonal parallel structure, guarantees stable and fast mold clamping & opening, shortens dry cycle time