SN400C

Skitek CNC Die Sinking EDM Machines-SN400C

Skitek CNC Die Sinking EDM Machines-SN400C With Reliable Spark Erosion Technology Achieves Best Surface Finish. Sinker Edm Machines With Column Movement Has The Advanced World Leading Electric Discharge Machining Technology

Travel(mm)(X-Y-Z)

400-300-300

Work Tank Size(mm)

850x610x505

Surface Finish(Best)

≤0.7µm Ra

SPECIFICATION

SN400C

Unit

Values

X-Axis Travel

Mm

400

Y-Axis Travel

Mm

300

Z-Axis Travel

Mm

300

Work Table Size

Mm

700x400

Distance Between T-Type Grid Plate And Work Table (Max/Min)

Mm

580/280

Machine Size

Mm

1780x2100x2500

Work Tank Size

Mm

850x610x505

Oil Tank Capacity

Litre

500

Electrode Weight

Kgs

50

Workpiece(Max)

Kgs

400

Machine Weight

Kgs

3850

Processing Current(Max)

Amp

30A

Surface Finish(Best)

µm Ra

≤0.07

- The machine’s exceptional stability and rapid performance in precision processing make it exceptionally efficient for production purposes.

- The machine offers versatile electrode and mould processing capabilities

- Special dedicated circuit for tungsten carbide machining

- Equipped with Panasonic AC Servo Drive

- Anti arc control system to prevent the damage to work piece

- Rise and fall tank

- The machine’s exceptional stability and rapid performance in precision processing make it exceptionally efficient for production purposes.

- The machine offers versatile electrode and mould processing capabilities

- Special dedicated circuit for tungsten carbide machining

- Equipped with Panasonic AC Servo Drive

- Anti arc control system to prevent the damage to work piece

- Rise and fall tank

- Advanced encoder for precise procedure tracking

- Industrial 4.0 EtherCAT communication processing system

- Remote access facilitates the execution of a wide range of adjustments, diagnostics, and monitoring procedures

- 15" TFT Display with 1 micron resolution

- It comes equipped with a touch panel, USB ports, and Ethernet ports, enabling internet connectivity. Facilitating remote and real time monitoring

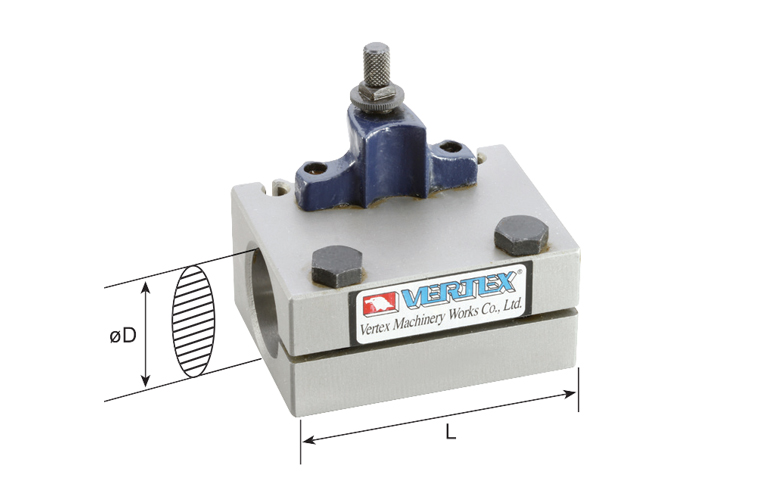

- Electrode holder axis corrector assembly with piding head for easy alignment

- Featuring an advanced automation interface that supports remote command transmission, machine positioning, processing, machine status feedback, and automatic processing scheme matching

- 15" TFT Display with 1 micron resolution

- It comes equipped with a touch panel, USB ports, and Ethernet ports, enabling internet connectivity. Facilitating remote and real time monitoring

- Electrode holder axis corrector assembly with piding head for easy alignment

- Featuring an advanced automation interface that supports remote command transmission, machine positioning, processing, machine status feedback, and automatic processing scheme matching

- It achieves positioning accuracy at nanometre level (0.0001 mm)

- It offers support for the C axis and ATC (optional)

- Achieve best surface finish ≤0.07 µm Ra

- Achieve best surface finish ≤0.07 µm Ra