NP1060L

EXCETEK NP Series CNC Wire EDM NP1060L

EXCETEK CNC Wire EDM NP1060L Are Finest CNC Wire EDM Machines With Linear Motor Drive, Excellent Precision And Reliability.

Travel

Table Travel Of XY - 1000 X 600 Mm (39.4" X 23.6")

Axes Control

Number Of Axes Controlled - XY Axis Linear Motor, UVZ Axis AC Servo Motor

Machine Dimensions

Machine Dimensions - 4210/4310 X 3260 X 2590/2890 Mm

SPECIFICATION

NP1060L

Unit

Values

- Rotary Table

- Auto-Measurement System

- Wire Chopper

- Rotary Table

- Auto-Measurement System

- Wire Chopper

Machine Feature

- Rigid U, V truss design.

- Stainless steel work table with a hardness HRC 50°.

- Cast machine base was designed using FEA to achieve high rigidity.

- Extra-wide machine base.

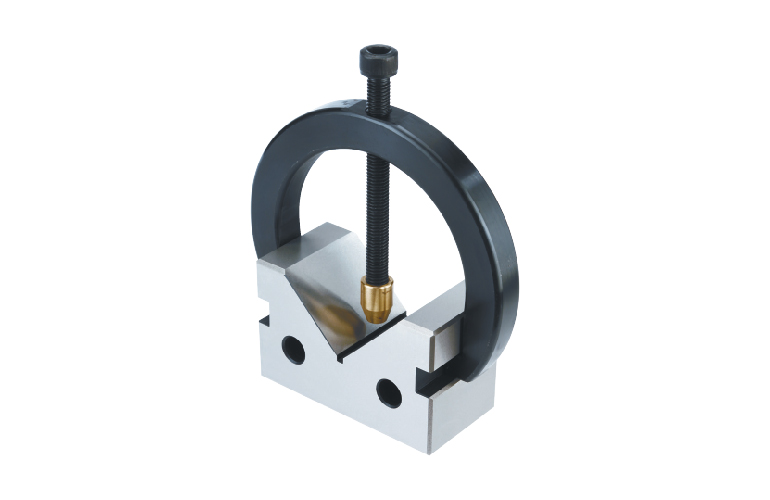

Four-sided hardened Stainless Steel Table

Four-sided hardened Stainless Steel Table

Controller and Generator System

The W6 controller is designed to deliver

- CNC Device: Industrial PC

- CPU: 64-bit high speed CPU

- Operation Interface: 19 LCD touch-screen, Keyboard, Mouse

- Input Interface: LAN, USB driver, RS-232

- Memory capacity: 32 GB SSD

- Min. command unit: 0.0001 mm (0.000004")

- Max. programmable dimension: ±9999.9999 mm

- Unit: Metric/Inch switchable

Auto Wire Threading

Reliable Auto Wire Threading System

- The EXCETEK AWT is a simple, proven and reliable design that provides continuous unmanned operation day and night. This advanced technology enables re-threading within the kerf. Wire is annealed and guided by means of a water jet which can thread through workpieces up to 400m.

- The EXCETEK AWT is a simple, proven and reliable design that provides continuous unmanned operation day and night. This advanced technology enables re-threading within the kerf.

- Wire is annealed and guided by means of a water jet which can thread through workpieces up to 400m.

High speed Auto Wire Threading System

- Workpiece thickness 100mm

- Annealing and cutting the wire takes 10 seconds.

- Threading the wire takes 10 seconds.

200mm submerged threading

400mm thickness can re-thread within the kerf

Auto Wire Threading

Reliable Auto Wire Threading System

- The EXCETEK AWT is a simple, proven and reliable design that provides continuous unmanned operation day and night. This advanced technology enables re-threading within the kerf. Wire is annealed and guided by means of a water jet which can thread through workpieces up to 400m.

- The EXCETEK AWT is a simple, proven and reliable design that provides continuous unmanned operation day and night. This advanced technology enables re-threading within the kerf.

- Wire is annealed and guided by means of a water jet which can thread through workpieces up to 400m.

High speed Auto Wire Threading System

- Workpiece thickness 100mm

- Annealing and cutting the wire takes 10 seconds.

- Threading the wire takes 10 seconds.

200mm submerged threading

400mm thickness can re-thread within the kerf

Power Generator System

Discharge frequency and control

- The generator is designed to reduce system load and stabilize cutting conditions.

- ASIC chip technology is used to increase circuit stability and discharge performance.

- Real-time feedback of the discharge and cutting status is monitored and adjusted to reach optimum speed and accuracy.

Electrolysis free cutting

The Power Generator is equipped with EF Technology which enhances cutting efficiency and speed, while nearly eliminating the effects of electrolysis during discharge.

RTS (Real Time Sparking)

Short response time provides feedback to ineffective discharges and adjusts conditions to improve cutting efficiency.

Digital Power Management (DPM)

The Digital Power Management (DPM) system detects the discharge

density, area, and capacity and automatically adjusts the power, wire

tension and flushing to improve cutting speed while maintaining

consistent accuracy through varying workpiece thicknesses.