FV56T

YCM CNC Vertical Machining Center FV56T

S&T Engineers Is The Authorised Distributors Of YCM VMC Machines In India. YCM High Precision And Reliable FV Series High Speed Compact VMC Machine For Die And Mould Application. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 15000 Spindle Taper (Opt.) - BBT30

Travel

Travel(mm)(X-Y-Z) - 560-410-450

ATC

Tool Magazine Capacity (Opt.)(T) - 16 (20)

SPECIFICATION

FV56T

Unit

Values

Tough and durable MEEHANITE castings deliver exceptional cutting stability and consistent accuracy - the massive, rigid internally ribbed construction reduces damping effect for superb part finishing.

|

Tough and durable MEEHANITE castings deliver exceptional cutting stability and consistent accuracy - the massive, rigid internally ribbed construction reduces damping effect for superb part finishing.

|

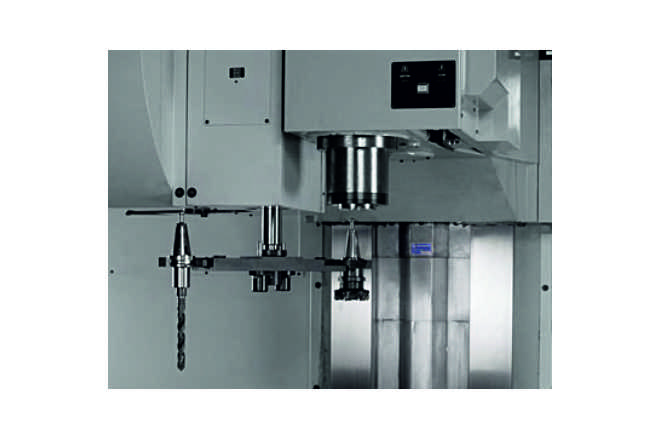

Reliable ATC Unit

- Fast and reliable roller gear cam ATC allows ATC time in 3.5 seconds, lower the idle time and enhances the machining efficiency.

- The ATC units were running tested more than 72 hours before their mass production to ensure high reliability.

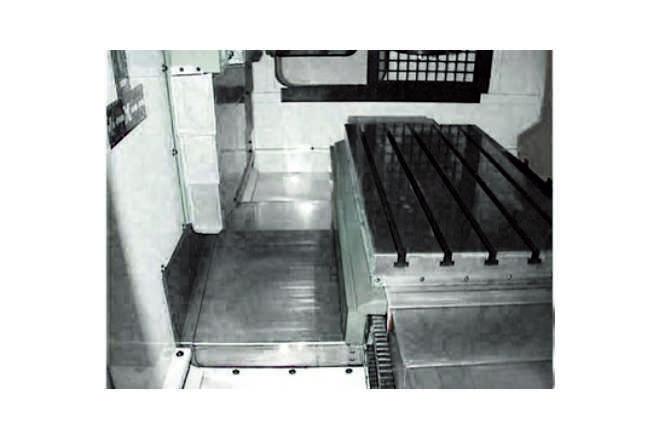

Complete chips disposal system

- Ensure the cleanness of the machining environment. Optional flush coolant can be used to prove the chips disposal efficiently.

- Screw type chip conveyor makes the chips disposal more easily & efficiently.

- Complete set of the Y-axis back side plate well protects the guide-way for durable operation.

Complete chips disposal system

- Ensure the cleanness of the machining environment. Optional flush coolant can be used to prove the chips disposal efficiently.

- Screw type chip conveyor makes the chips disposal more easily & efficiently.

- Complete set of the Y-axis back side plate well protects the guide-way for durable operation.