UV650

YCM 5-Axis Machining Center UV650

S&T Engineers Is The Authorised Distributors Of YCM 5-Axis VMC Machines In India. YCM High Precision And Reliable UV Series High Performance 5-Axis Machines. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 12,000 ( 15,000 ) Spindle Taper (Opt.) - BBT40

Travel

Travel(mm)(X-Y-Z(Opt.)) - 620-520-460

ATC

Tool Magazine Capacity (Opt.)(T) - 40 (60)

SPECIFICATION

UV650

Unit

Values

Spindle Speed (Opt.)

Rpm

12,000 ( 15,000 )

Spindle Power (Opt.)

KW

17 ( 17 )

Spindle Taper (Opt.)

-

BBT40

X-Axis Travel

Mm

620

Y-Axis Travel

Mm

520

Z-Axis Travel

Mm

460

Distance Between Spindle Center And Table Top

Mm

150 ~ 610

Swivel Head Degree

Degree

200° ( -90° ~ +110° )

Rotary Table Size

Mm

360°

Table Size

Mm

ø650

No. T-Slot X Size X Pitch

Mm

5 X 18 X 100

Max. Load On Table

Kg

Load-Horizontal(0∘~45∘):300、Load-Tilting(45∘~90∘): 200

X/Y/Z Rapid Feedrate

M/min

36 / 36 / 36

Cutting Feedrate

Mm/min

1~20,000

Tool Magazine Capacity (Opt.)

T

40 (60)

Tool Weight

Kg/pc

6

Max. Tool Dimension (W/O Adjacent Tools)

Mm

40T:ø76 X 250 (ø125 X 250 ) ( 48T/60T:ø76 X 250 (ø125 X 250 ) )

Machine Weight

Kg

10000

Accurate and Thermally

- Linear scales are mounted in X/Y/Z-axis and encoders in the B & C axis allowing for the most demanding machining accuracies.

- The X/Y/Z-axis are fitted with high precision roller guideways and fixed pre-tensioned, double-nut, direct drive ballscrews, allowing for fast and accurate machining.

Accurate and Thermally

- Linear scales are mounted in X/Y/Z-axis and encoders in the B & C axis allowing for the most demanding machining accuracies.

- The X/Y/Z-axis are fitted with high precision roller guideways and fixed pre-tensioned, double-nut, direct drive ballscrews, allowing for fast and accurate machining.

B/C-axis Rotary Table

- High precision rotary encoders in the B and C

- axes as a standard feature, allowing for the most demanding machining accuracies.

- Durable 2-axis tilt/rotary table allows fast, accurate

- machining of complex 5-axis components.

- The tilt-rotary table features a full circular hydraulic braking system that provides rigid B/C-axis clamping during fixed rotary-axis machining applications.

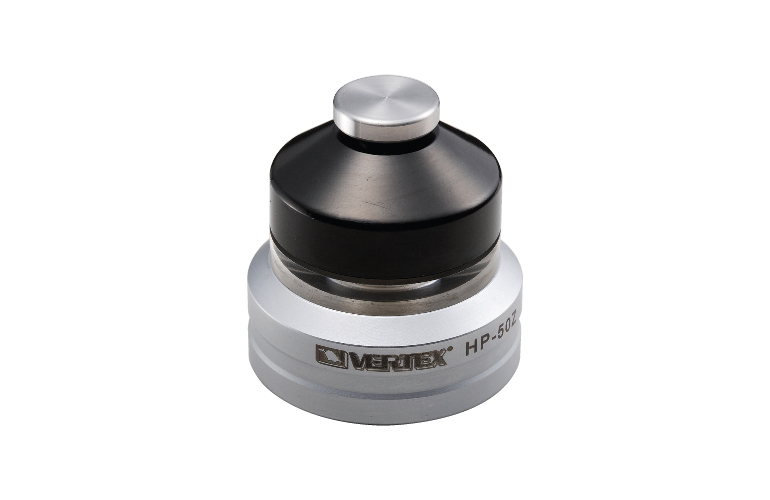

YCM In-house IDD Spindle

- The YCM IDD spindle design provides power, speed, and stiffness required for the

- most adverse machining applications while providing long spindle life.

- Ceramic bearings help to minimize heat and provide thermal stability improving overall

- machining accuracy.

- Powerful 17 kW max. hollow shaft spindle motor – allows machining of the toughest

- materials, while also providing with fine surface finishes and the ability to add up to

- CTS 20 bar (1,000 psi) coolant through spindle (CTS) easily.

YCM In-house IDD Spindle

- The YCM IDD spindle design provides power, speed, and stiffness required for the

- most adverse machining applications while providing long spindle life.

- Ceramic bearings help to minimize heat and provide thermal stability improving overall

- machining accuracy.

- Powerful 17 kW max. hollow shaft spindle motor – allows machining of the toughest

- materials, while also providing with fine surface finishes and the ability to add up to

- CTS 20 bar (1,000 psi) coolant through spindle (CTS) easily.

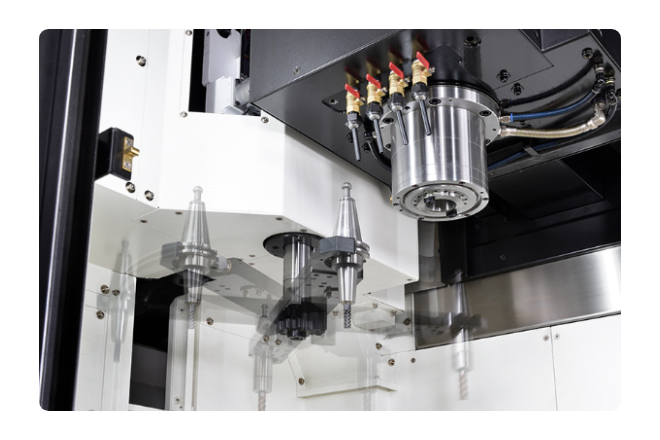

Tool Magazine

- Chain type 40T magazine as standard

- Wide selection of optional tool magazine, including 48T / 60T

- Absolute encoder ATC system tracks tool pot position in the event of a mishap

Automatic Tool Changer

- Tool to Tool time: 1.8 sec.

- Standard ATC auto door minimizes chips and coolant from entering the tool magazine area.

- This design incorporates an inverter type cam-box-motor for easy ATC recovery in the event of a mishap. The tool change arm is designed for low inertia allowing precise positioning and long service life.

Automatic Tool Changer

- Tool to Tool time: 1.8 sec.

- Standard ATC auto door minimizes chips and coolant from entering the tool magazine area.

- This design incorporates an inverter type cam-box-motor for easy ATC recovery in the event of a mishap. The tool change arm is designed for low inertia allowing precise positioning and long service life.