NMV106A

YCM CNC Vertical Machining Center NMV106A

S&T Engineers Is The Authorised Distributors Of YCM VMC Machines In India. YCM High Precision And Reliable NMV Series VMC Machines With Box Type Guides Well Suited For Heavy Duty Die And Mould Cutting Applications. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 12,000 (8,000 / 10,000 GEAR BOX) Spindle Taper (Opt.) - BBT40

Travel

Travel(mm)(X-Y-Z) - 1020-600-600

ATC

Tool Magazine Capacity (Opt.)(T) - 24 (30/40)

SPECIFICATION

NMV106A

Unit

Values

Spindle Speed (Opt.)

Rpm

12,000 (8,000 / 10,000 GEAR BOX)

Spindle Power (Opt.)

KW

18.5(18.5/18.5)

Spindle Taper (Opt.)

BBT40

X-Axis Travel

Mm

1020

Y-Axis Travel

Mm

600

Z-Axis Travel

Mm

600

Distance Between Spindle Nose & Table Top

Mm

80~680(330~930)

Table Size

Mm

1,120 X 600

No. T-Slot X Size X Pitch

Mm

5 X 18 X 100

Max. Load On Table

Kg

800

X/Y/Z Rapid Feedrate

M/min.

36/36/24

Cutting Feedrate

Mm/min.

1~20,000

Tool Magazine Capacity (Opt.)

T

24 (30/40)

Tool Weight

Kg/pc

6

Max. Tool Dimension (W/O Adjacent Tools)

Mm

ø90 X 300 (ø140x 300)

Machine Weight

Kg

6500

High Rigidity Structural Design

- Adopted consistent production process, box guideway type models with high shock absorption and wear resistance, are the best for heavy cutting.

- The rigid body construction makes for uncompromising precision and rigidity.

- Finite Element Method analysis (FEM) is adopted to simulate the structural deformation of the body under various conditions, integrated with YCM hand scrapping skills for box guideways, which ensures the best accuracy and life.

- Boxway design on three axis is suitable for heavy cutting.

- The wide span 800 mm Y-axis with rigid dual-wall saddle design fully supports table movement.

- No counter weight on Z-axis provides the best dynamic accuracy.

High Rigidity Structural Design

- Adopted consistent production process, box guideway type models with high shock absorption and wear resistance, are the best for heavy cutting.

- The rigid body construction makes for uncompromising precision and rigidity.

- Finite Element Method analysis (FEM) is adopted to simulate the structural deformation of the body under various conditions, integrated with YCM hand scrapping skills for box guideways, which ensures the best accuracy and life.

- Boxway design on three axis is suitable for heavy cutting.

- The wide span 800 mm Y-axis with rigid dual-wall saddle design fully supports table movement.

- No counter weight on Z-axis provides the best dynamic accuracy.

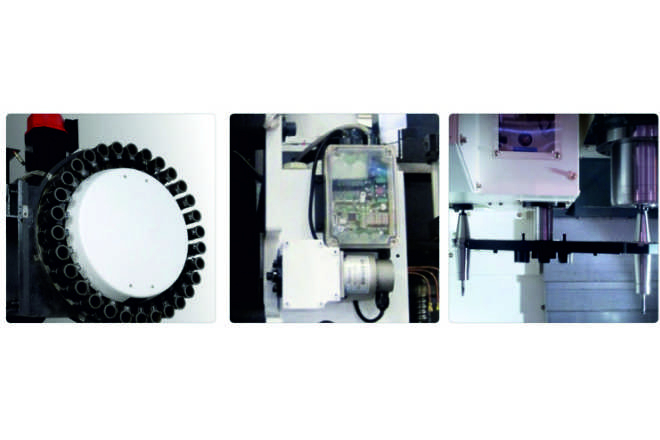

YCM In-house IDD Spindle

- Symmetrical Head Stock design homogeneously absorbs the thermal expansion and avoids thermal deformation.

- High precision ceramic ball bearing with low centrifugal force, low vibration and low coefficient of thermal expansion.

- Tool unclamping cushion design extends spindle bearing life by protecting spindle bearing from tool unclamping force.

- 12,000 rpm direct-drive spindle features high precision helical springs for excellent balance, suitable for parts machining.

- The optional 8,000 rpm spindle design incorporates gear transmission is capable of reaching 45.04 kgf-m 325.78 lb-ft torque; perfect for casting and titanium machining.

- The optional 10,000 rpm spindle combines with gear transmission for heavy cutting. Even using the small-diameter tools for high speed cutting can achieve refined machining roughness (Spindle cooling system: std.)

High Stability Tool Magazine

- The bi-directional tool selection design takes the shortest random path.

- The standard tool magazine is equipped with 24T, for more machining demands, the tool magazine can be expanded to 30T/40T.

- Absolute encoder and inventor control in ATC improve the tool change time 1.8 sec. only.

- Tool change speed can be adjustable.

High Stability Tool Magazine

- The bi-directional tool selection design takes the shortest random path.

- The standard tool magazine is equipped with 24T, for more machining demands, the tool magazine can be expanded to 30T/40T.

- Absolute encoder and inventor control in ATC improve the tool change time 1.8 sec. only.

- Tool change speed can be adjustable.

Automatic Tool Magazine Door Design

- Pneumatic cylinder driven.

- Prevent coolant and chips from entering tool magazine.

The Z-axis is outside support design

- The best L/W ratio.

- Secure the utmost cutting rigidity.

- The Z-axial movement is very smooth.

The Z-axis is outside support design

- The best L/W ratio.

- Secure the utmost cutting rigidity.

- The Z-axial movement is very smooth.

Brand New Exterior Design

- Full enclosure exterior (including top cover).

- Convertible side window for convenient chip removal.

- Aesthetic rear cover design.

- Smooth chip removal.

- Dual chip augers combined with chip conveyor for fast chip disposal (opt.)