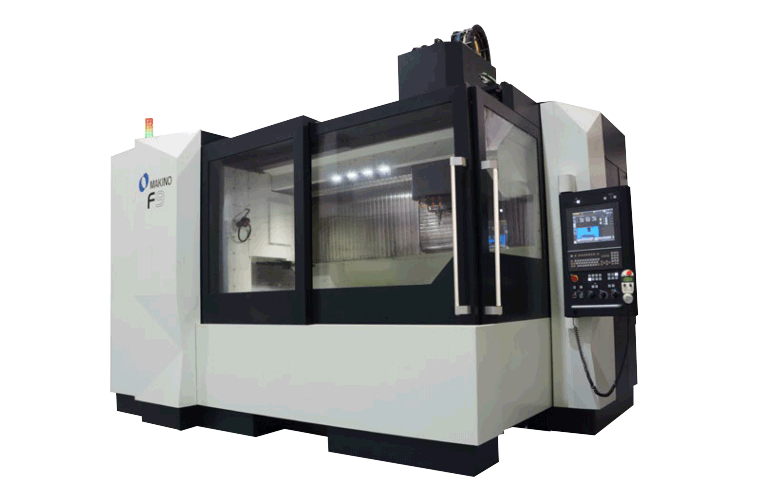

SR-600/M

SKITEK Medium Speed CNC Wire EDM SR-600/M

SKITEK Medium Speed CNC Wire EDM SR-600/M Molybdenum Recirculating Wire Cnc Edm. Cost Effective, Excellent Surface Finish, Best Reliable Edm Machine

Water Tank Size(W X L X H) (mm)

1100x700x670

Axis Control

4 Axis Step Sub Division Control

Surface Finishing

Ra≤0.8um

SPECIFICATION

SR-600/M

Unit

Values

- SKITEK presents cutting-edge wire EDM machines of unrivaled quality. Our dedication lies in advancing the industry, meeting current demands, and understanding the usage of EDM machines

- We inspire confidence by offering innovative EDM solutions that go beyond customer satisfaction. The SKITEK Medium Speed ecirculating Wire CNC Wire EDM is meticulously engineered to enhance CNC operations’ efficiency

- Industries such as Aerospace, Die Moulding, Automotive, Medical Device Manufacturing, and Tool Room Accessories Manufacturing rely on SKITEK Medium Speed Recirculating Wire CNC Wire EDM machines

- These cutting-edge machines masterfully sculpt intricate shapes with unparalleled precision and effortlessly handle a vast array of materials.

- SKITEK presents cutting-edge wire EDM machines of unrivaled quality. Our dedication lies in advancing the industry, meeting current demands, and understanding the usage of EDM machines

- We inspire confidence by offering innovative EDM solutions that go beyond customer satisfaction. The SKITEK Medium Speed ecirculating Wire CNC Wire EDM is meticulously engineered to enhance CNC operations’ efficiency

- Industries such as Aerospace, Die Moulding, Automotive, Medical Device Manufacturing, and Tool Room Accessories Manufacturing rely on SKITEK Medium Speed Recirculating Wire CNC Wire EDM machines

- These cutting-edge machines masterfully sculpt intricate shapes with unparalleled precision and effortlessly handle a vast array of materials.

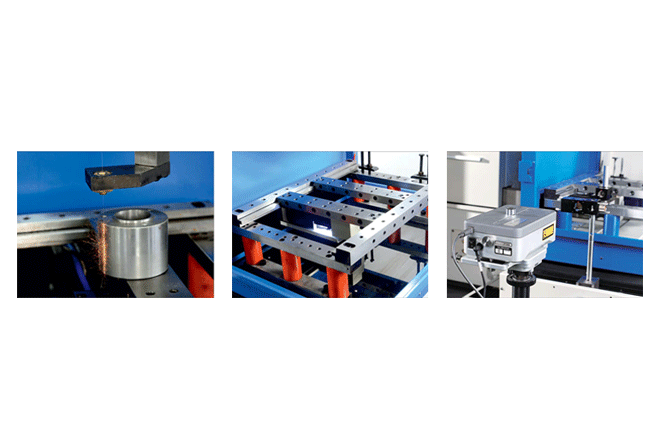

- The machine includes automatic center finding and automatic edge finding capabilities.

- The machine enables automatic adjustment of wire verticality.

- The Z - axis can rapidly elevate and automatically return to the memory position.

- Maximum taper of ±10° / 80 mm can be cut.

Sample Components

Sample Components