F8

Makino (3-Axis CNC VMC Machine) - F8 For Larger Die & Mould

Makino 3-Axis Vertical Machining Center Machine Specially For Larger Die And Mould Component Machining With High Precision And Accuracy For Demanding Cnc Metal Cutting Jobs. Experience Smooth Cutting With High-speed Hard Milling And More Accuracy For Complex 3-D Geometry With Makino Cnc Vmc's.

Table(XxY)(mm)

1550x800

Travel(XxYxZ)(mm)

(1300x800x650)

Spindle

CAT50

SPECIFICATION

F8

Unit

Values

Spindle

Makino Spindles are best in the global competitive market.

The heart of Makino machines is the spindle, which distinguishes them through features such as lower power consumption, improved surface quality, and minimized vibrations.

Master-crafted spindles

Each spindle is dedicated to specific machines, ensuring that they are meticulously engineered to deliver optimal performance for their respective applications.

Spindle

Makino Spindles are best in the global competitive market.

The heart of Makino machines is the spindle, which distinguishes them through features such as lower power consumption, improved surface quality, and minimized vibrations.

Master-crafted spindles

Each spindle is dedicated to specific machines, ensuring that they are meticulously engineered to deliver optimal performance for their respective applications.

Ball Screw Core Cooling

Cooling oil controlled to the machine temperature is circulated through the inside of the ball screws to minimise or control heat generation during high-speed movement.

In addition, cooling oil is also circulated to the support bearings providing the dual effect of cooling and increasing the life.

Motor flange cooling

Cooling oil is circulated through the motor flange to prevent motor heat from being transferred to the machine.

High performance linear motion guideways provide extremely precise, anti-friction motion. In addition, pre-tensioned, dual supported, large diameter ball screws and powerful, direct-coupled, digital servo motors - tuned for peak performance -provide the stiffness and rigidity for the most challenging applications.

Fine ball screw motion provides greater precision for blends, matches and complex geometry applications.

Competitive solution for larger component machining

The F8 & F9 machines are designed to provide stiffness and rigidity for chatter-free cutting, agility expected from a hard milling machine and accuracies for tight-tolerance blends and matches typical of complex, 3-D contoured geometry associated with:

Plastic, die cast to blow molds

Stamping to forging

Prototype to production

Medical, electronics, aerospace, optical consumer products, to packaging

Center Console

Virtually eliminating adjustments during matching

Low vibration spindle even with using long cutters L/D=9

Competitive solution for larger component machining

The F8 & F9 machines are designed to provide stiffness and rigidity for chatter-free cutting, agility expected from a hard milling machine and accuracies for tight-tolerance blends and matches typical of complex, 3-D contoured geometry associated with:

Plastic, die cast to blow molds

Stamping to forging

Prototype to production

Medical, electronics, aerospace, optical consumer products, to packaging

Center Console

Virtually eliminating adjustments during matching

Low vibration spindle even with using long cutters L/D=9

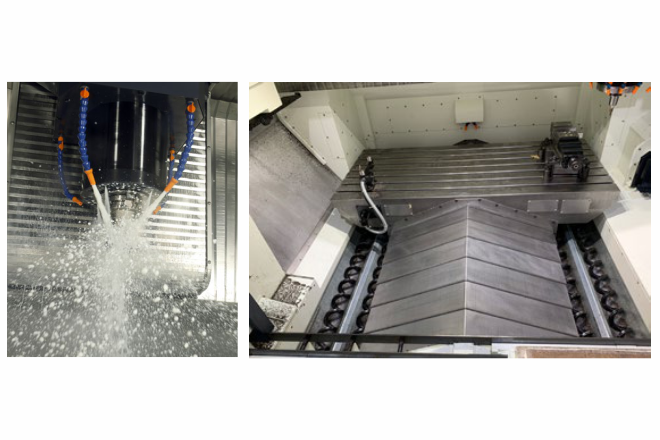

Efficient Chip Removal

Through-spindle air (optional specification)

Air is supplied from the tool tip and holder. Through-spindle coolant (1.5 MPa and 3.0 MPa) (optional specification)

Coolant is supplied from the inside of the holder through the tool tip.

Within the work zone, chip and coolant recovery is very quick and efficient due to a number of design features. All internal chip and splashguard surfaces are steeply sloped. High center or T shaped tele-covers and flushing nozzles ensure that all chips and coolant are directed into the integral chip trough, with a dual spiral screw design that provides a four auger chip management system. Chips and coolant are transferred to a large capacity chip and coolant recovery system conveniently located at the rear of the machine.

An optional lift up chip conveyor can be installed at the rear of the machine to further improve the chip management of the machine.