TV2110B

YCM CNC Vertical Machining Center TV2110B

S&T Engineers Is The Authorised Distributors Of YCM VMC Machines In India. YCM High Precision And Reliable TV Series VMC Machines With Box Type Guides Well Suited For Heavy Duty Cutting Applications. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 6,000 (10,000)Spindle Taper (Opt.) - BT50(BBT50)

Travel

Travel(mm)(X-Y-Z) - 2100-1020-762

ATC

Tool Magazine Capacity (Opt.)(T) - 24 (32/40)

SPECIFICATION

TV2110B

Unit

Values

Spindle Speed (Opt.)

Rpm

6,000 (10,000)

Spindle Power (Opt.)

KW

25 ( 45 )

Spindle Taper (Opt.)

BT50(BBT50)

X-Axis Travel

Mm

2100

Y-Axis Travel

Mm

1020

Z-Axis Travel

Mm

762

Distance Between Spindle Nose & Table Top

Mm

200~962(450~1,212)

Table Size

Mm

2,300 X 1,020

No. T-Slot X Size X Pitch

6 X 22 X 150

Max. Load On Table

Kg

7000

X/Y/Z Rapid Feedrate

M/min.

12/12/12

Cutting Feedrate

Mm/min.

1~5,000

Tool Magazine Capacity (Opt.)

T

24 (32/40)

Tool Weight

Kg/pc

20

Max. Tool Dimension (W/O Adjacent Tools)

Mm

24T : ø110 X 350 (ø190 X 350) 32T/40T : ø120 X 350 (ø240 X 350)

Machine Weight

Kg

25500

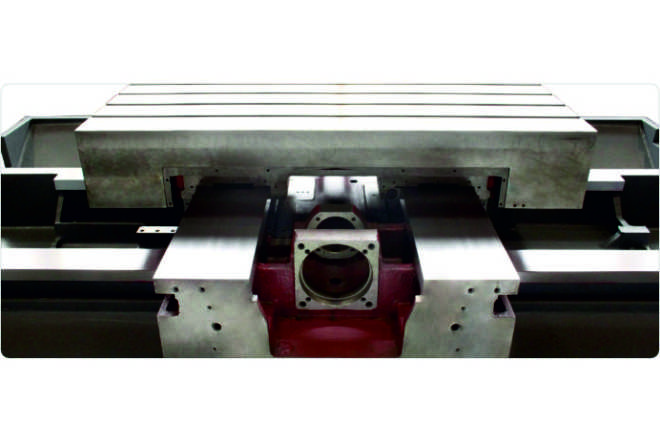

The Best Force Flow T-base Design

- The unique T-base structural design has been awarded a patent from Taiwan, China and the U.S.A. Its overhang free table movement is supported by highly rigid MEEHANITE® castings to ensure the best dynamic leveling accuracy, machining rigidity and durability.

- The long travel of X-axis lies on the top of the base, where the saddle moves along the full stroke; the cross Y-axis saddle supports the work table.

- The T-base rigid structure has full stroke support and do not have overhang problem guarantees the most dynamic leveling accuracy.

The Best Force Flow T-base Design

- The unique T-base structural design has been awarded a patent from Taiwan, China and the U.S.A. Its overhang free table movement is supported by highly rigid MEEHANITE® castings to ensure the best dynamic leveling accuracy, machining rigidity and durability.

- The long travel of X-axis lies on the top of the base, where the saddle moves along the full stroke; the cross Y-axis saddle supports the work table.

- The T-base rigid structure has full stroke support and do not have overhang problem guarantees the most dynamic leveling accuracy.

- Standard gearhead spindle of maximum of 6,000rpm high-speed with the maximum of 15kW/18.5kW 25HP/20HP power output and 48kg-m 347.19lb-ft torque.

- n Spindle speed of up to 10,000rpm with IDD (Isolated Direct Drive) design, coupled with oil lubrication that can lower heat deviation, improve spindle accuracy and extend bearing life. Spindle power 18.5kW / 22kW 24.8HP/29.5HP without gearbox, electric speed shift with spindle motor, maximum torque of 36kgf-m. (option).

- The quill type spindle housing is with cooling system to assure the best temperature control of the spindle head, and for the best machining results.

- Deployed with precise angular contact ceramic ball bearings for extra axial and radial rigidity to fit the requirements of heavy cutting.

Fast & Reliable ATC System

- Number of tool posts in magazine can be selected for 24T/32T/40T.

- The arm type ATC sysstem is driven by roller gear cam to increase the work efficiency.

Fast & Reliable ATC System

- Number of tool posts in magazine can be selected for 24T/32T/40T.

- The arm type ATC sysstem is driven by roller gear cam to increase the work efficiency.

Humanized Operation Panel

- The swivel operation panel of appropriate height and clear modular switches can be operated easily.

- Clearly display the signals and alarm messages.

- Detachable MPG handwheel is installed for operational convenience.