NH500A

YCM CNC Horizontal Machining Center NH500A

S&T Engineers Is The Authorised Distributors Of YCM HMC Machines In India. YCM High Precision And Reliable Fast Spindle, Rapid Speeds NH Series Pallet Changing HMC Machines Well Suited For High Productive Application. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 15000 Spindle Taper (Opt.) - BBT40

Travel

Travel(mm)(X-Y-Z) - 800-730-800

ATC

Tool Magazine Capacity (Opt.)(T) - 60(120)

SPECIFICATION

NH500A

Unit

Values

Spindle Speed (Opt.)

Rpm

15,000

Spindle Power (Opt.)

KW

37

Spindle Taper (Opt.)

-

BBT40

X-Axis Travel

Mm

800

Y-Axis Travel

Mm

730

Z-Axis Travel (Opt.)

Mm

800

Distance Between Center And Table Top

Mm

50~780

Distance Between Spindle Nose And Table Center

Mm

150~950

Table Size

Mm

500 X 500

Max. Load On Table

Kg

500

Max. Work Dimensions

Mm

φ880 X 1000

Height From Table Top To Floor

Mm

1174

APC Time

Sec

11

X/Y/Z Rapid Feedrate

M/min

60/60/60

Cutting Feedrate

Mm/min

1~40,000

Tool Magazine Capacity (Opt.)

T

60 (120)

Tool Weight

Kg/pc

10

Max. Tool Dimension (W/O Adjacent Tools)

Mm

Ф80x400(Ф160x400)

Machine Weight

Kg

13,490~14,390

High Rigidity Structural Design

- One piece T-type base structure with rib construction for unprecedented rigidity.

- Dual-wall column design for enhancing rigidity and durability.

- Adopted FEM analysis for lightweight design to improve G value that can prolong ballscrew life and reduce energy consumption.

High Rigidity Structural Design

- One piece T-type base structure with rib construction for unprecedented rigidity.

- Dual-wall column design for enhancing rigidity and durability.

- Adopted FEM analysis for lightweight design to improve G value that can prolong ballscrew life and reduce energy consumption.

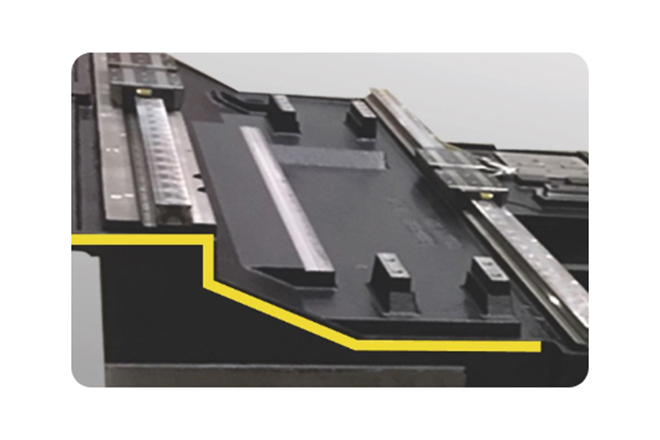

Stepped Design on X-axis

- Two X-axis guideways are positioned at different height to increase stable and reliable rapid axial movement.

- Compact column design is able to achieve higher acceleration and performance.

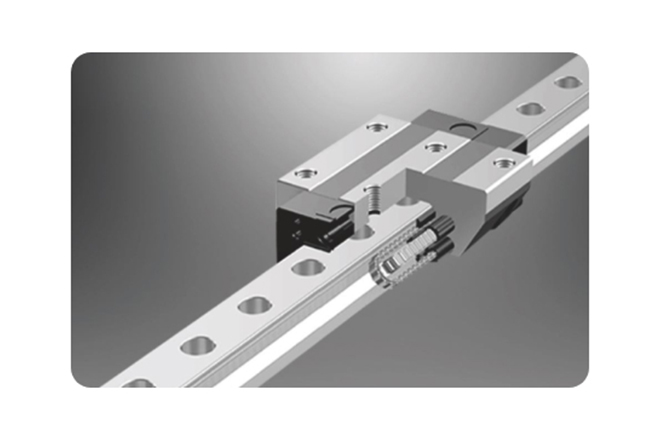

All Roller Type Guideways

- XYZ axes are equipped with roller guideways to increase rigidity and accuracy.

- High dynamic AC servo driven pre-tensioned ball screws, delivering high control qualities.

All Roller Type Guideways

- XYZ axes are equipped with roller guideways to increase rigidity and accuracy.

- High dynamic AC servo driven pre-tensioned ball screws, delivering high control qualities.

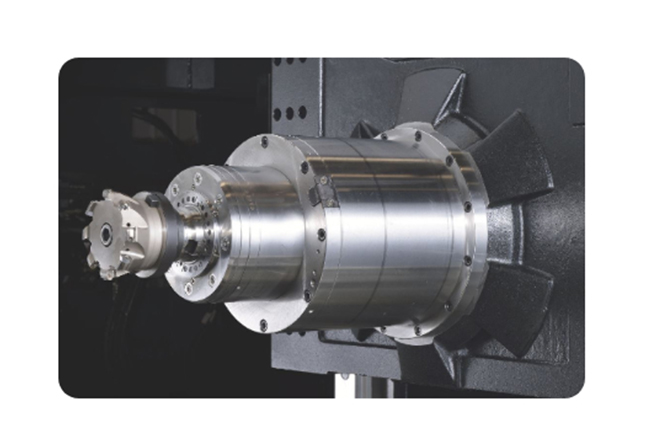

Powerful IDD Spindle

- The standard IDD spindle design, easy for maintenance 15,000 rpm max. spindle speed with 37 kW output delivers 244 Nm torque.

- The powerful spindle utilizes high precision ceramic ball bearings.

- The spindle oil cooling system effectively minimizes thermal deformation.

High Performance Built-in Motorized Spindle (opt.)

- The max. spindle speed reaches up to 20,000 rpm with 22.5 kW output delivers 61 Nm torque.

- Micro oil-air lubrication for angular ceramic ball bearings prolongs spindle life.

- Circulated oil jacket cooling system minimize thermal deformation, ensuring high accuracy.

- Easy spindle unit replacement reduces maintenance time.

High Performance Built-in Motorized Spindle (opt.)

- The max. spindle speed reaches up to 20,000 rpm with 22.5 kW output delivers 61 Nm torque.

- Micro oil-air lubrication for angular ceramic ball bearings prolongs spindle life.

- Circulated oil jacket cooling system minimize thermal deformation, ensuring high accuracy.

- Easy spindle unit replacement reduces maintenance time.

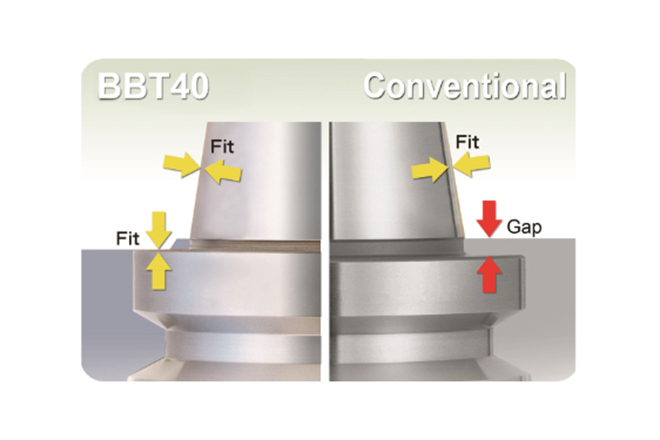

BBT40 Dual-Contact Spindle Taper

- Equipped with BBT dual-contact to improve cutting capacity and accuracy, also enhance spindle and tool life.

- Coolant through spindle system: 20 bar (std.) / 70 bar (opt.).

- Spindle air seal protected.

- Labyrinth protection design.