DCV3018A-5AX

YCM Double Column Machining Center DCV3018A-5AX

S&T Engineers Is The Authorised Distributors Of YCM Double Column VMC Machines In India. YCM High Precision And Reliable DCV Series 5-AXIS Double Column Vmc Machines For High Productivity Application. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 18000 Spindle Taper (Opt.) - HSK A63

Travel

Travel(mm)(X-Y-Z(Opt.)) - 3200-2400-762(1016)

ATC

Tool Magazine Capacity (Opt.)(T) - 40(60/120)

SPECIFICATION

DCV3018A-5AX

Unit

Values

Spindle Speed (Opt.)

Rpm

18,000

Spindle Power (Opt.)

KW

70

Spindle Taper (Opt.)

HSK A63

X-Axis Travel

Mm

3,200

Y-Axis Travel

Mm

2,400

Z-Axis Travel(Opt.)

Mm

762(1,016)

Distance Between Spindle Nose & Table Top

Mm

30" Vertical: 150-912 Horizontal: 430-1192 40" Vertical: 150-1116 Horizontal: 430-1446

Distance Between Columns

Mm

1,800

Table Size

Mm

3,000 X 1,500

No. T-Slot X Size X Pitch

Mm

8×22×180

Max. Load On Table

Kg

10,000

X/Y/Z Rapid Feedrate

M/min.

20/24/20

Cutting Feedrate

Mm/min.

1~20,000

Tool Magazine Capacity (Opt.)

T

40(60/120)

Tool Weight

Kg/pc

6

Max. Tool Dimension (W/O Adjacent Tools)

Mm

ø 76 X 300(ø125 X 300)

Machine Weight

Kg

32,000

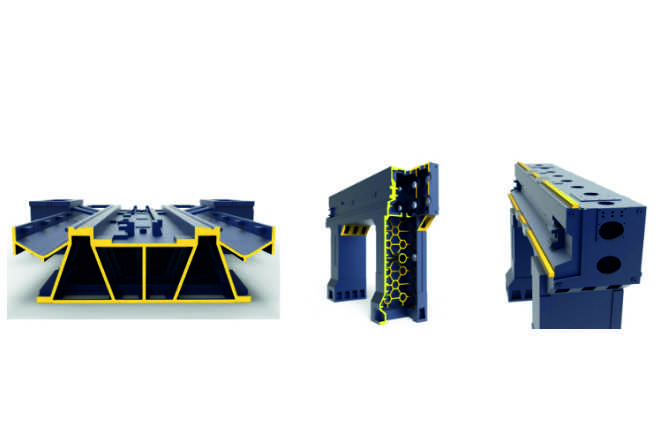

Reinforced Body Structure

- One-piece Column

- One-piece Base

- Ultimate rigidity and proportion of the headstock

- Internal double A type ribbed bed design through FEM analysis offers full support for table.

- 1,800 mm distance between columns increases the stability of machine

Reinforced Body Structure

- One-piece Column

- One-piece Base

- Ultimate rigidity and proportion of the headstock

- Internal double A type ribbed bed design through FEM analysis offers full support for table.

- 1,800 mm distance between columns increases the stability of machine

Extra Rigidity Guideways

- Roller type linear guideways on X / Y / Z-axis.

- Y axis linear guideways design with large span with horizontal and vertical directions which can take the saddle weight and machining force.

- Direct driven motors on Y / Z-axis reduce backlash and ensure perfect axial accuracy.

- X-axis is gearbox driven.

B/C-axis Head

- DD motor drive, no backlash.

- B/C axis rotary speed 100 rev/min.

- C-axis includes three roller bearings to increase rigidity and accuracy.

- B-axis high rigidity and high accuracy cross roller bearing.

- Heidenhain accuracy encoder included as standard.

- Pneumatic positioning clamping equipment.

- Over travel protection design.

- B-axis anti-drop function at power outage.

B/C-axis Head

- DD motor drive, no backlash.

- B/C axis rotary speed 100 rev/min.

- C-axis includes three roller bearings to increase rigidity and accuracy.

- B-axis high rigidity and high accuracy cross roller bearing.

- Heidenhain accuracy encoder included as standard.

- Pneumatic positioning clamping equipment.

- Over travel protection design.

- B-axis anti-drop function at power outage.

Unique Isolated Direct Drive Design

- Deliver maximum spindle speed of up to 18,000 rpm driven by 56/70kW motor