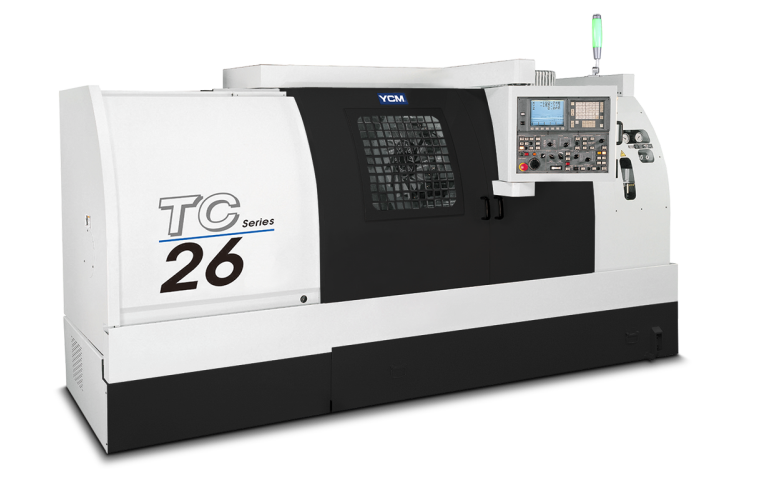

TC36

YCM Turning Center TC36

S&T Engineers Is The Authorised Distributors Of YCM Turning Center Machines In India. YCM High Precision And Reliable Box Type Guideway Turning Center Machines For High Productivity Application. Advanced Taiwanese CNC Machining Technology In India At Best Price

Machining Capacity

Max. Turning Diameter(mm) - ø590 Max. Turning Length(mm) - 1189

Main Spindle

Chuck Size - 12

Tailstock

Quill Taper - MT-4 Quill Stroke(mm) - 1080

SPECIFICATION

TC36

Unit

Values

Max. Turning Diameter

Mm

ø590

Max. Turning Length

Mm

1,189

Chuck Size

-

12

Spindle Nose

-

A2-8

Hole Through Spindle

Mm

ø105

Hole Through Draw Bar

Mm

ø93

Spindle Speed

Rpm

12"L: 7~180~719 H: 30~751~2,500

X-Axis Travel

Mm

310(295+15)

Z-Axis Travel

Mm

1250

"X - Axis Rapid Feedrate / Cutting Feedrate"

M/min / Mm/min

15 / 1~5,000

"Z - Axis Rapid Feedrate / Cutting Feedrate"

M/min / Mm/min

20 / 1~5,000

Main Spindle Motor

KW

22 / 26

Turret Type

-

Hydraulic TurretHydraulic Turret

Turret Capacity (opt.)

-

12 (10 / 8)

Swing Over Turret

Mm

ø640

Quill Taper

-

MT-4

Quill Stroke

Mm

1080

Machine Weight

Kg

7000

High Speed High Rigidity Turret

- The 12-station turret index is done by absolute detection, and no tool selection mistake is caused.

- The powerful turret of large diameter curvic coupling offers high precision and high rigidity in cutting performance.

High Speed High Rigidity Turret

- The 12-station turret index is done by absolute detection, and no tool selection mistake is caused.

- The powerful turret of large diameter curvic coupling offers high precision and high rigidity in cutting performance.

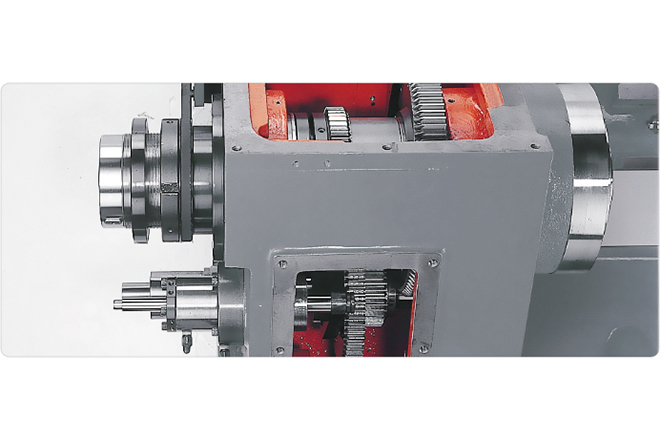

Powerful Headstock With Built-in Gears

- The spindle is equipped with high precision angular ball bearing and NN series bearing witch provides high precision and rigidity working condition.

- The inner diameter of the bearing is ø150mm ø5.91", and ø105mm ø4.13" of the spindle through hole. ø93mm ø3.66" of the drawbar through hole adapts large diameter bar stock jobs.

- The powerful spindle with built-in gears provides various speed transmissions. The max. output of torque reaches 140kgf-m 1,013 lb-ft, with max. spindle speed of 2,500rpm.

High Precision and High Rigidity Programmable Tailstock

- Using "M" code commands the quill stroke of the programmable tailstock can be hooked with a hydraulic hook to the saddle carriage and slide along the Z-axis stroke. Tailstock with live quill is standard.

High Precision and High Rigidity Programmable Tailstock

- Using "M" code commands the quill stroke of the programmable tailstock can be hooked with a hydraulic hook to the saddle carriage and slide along the Z-axis stroke. Tailstock with live quill is standard.