TCV3000A-5AX

YCM CNC Vertical Machining Center TCV3000A-5AX

S&T Engineers Is The Authorised Distributors Of YCM VMC Machines In India. YCM High Precision And Reliable TCV Series Long Travel Fixed Table VMC Machines Well Suited For Long Component Machining. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 12,000 (15,000 / 16,000 [Big Torque] )Spindle Taper (Opt.) - BBT40 (HSK-A63)

Travel

Travel(mm)(X-Y-Z) - 3000-800-800

ATC

Tool Magazine Capacity (Opt.)(T) - 40 (80)

SPECIFICATION

TCV3000A-5AX

Unit

Values

Spindle Speed (Opt.)

Rpm

12,000 (15,000 / 16,000 [Big Torque] )

Spindle Power (Opt.)

KW

25 ( 25/50 )[HDH]

Spindle Taper (Opt.)

BBT40 (HSK-A63)

X-Axis Travel

Mm

3000

Y-Axis Travel

Mm

800

Z-Axis Travel

Mm

800

Distance Between Spindle Nose & Table Top

Mm

0~800(V);300~1,100(H) (0~800(V);336~1,136(H)[Big Torque] )

X-Axis Travel Working In 2 Areas

Mm

2 X 1,100

Table Size

Mm

3,500 X 800

No. T-Slot X Size X Pitch

Mm

7 X 18 X 100

Max. Load On Table

Kg

3000

X/Y/Z Rapid Feedrate

M/min.

40/40/40

Cutting Feedrate

Mm/min.

1~10,000

Tool Magazine Capacity (Opt.)

T

40 (80)

Tool Weight

Kg/pc

6

Max. Tool Dimension (W/O Adjacent Tools)

Mm

ø76 X 300(ø125 X 300)

Machine Weight

Kg

24700

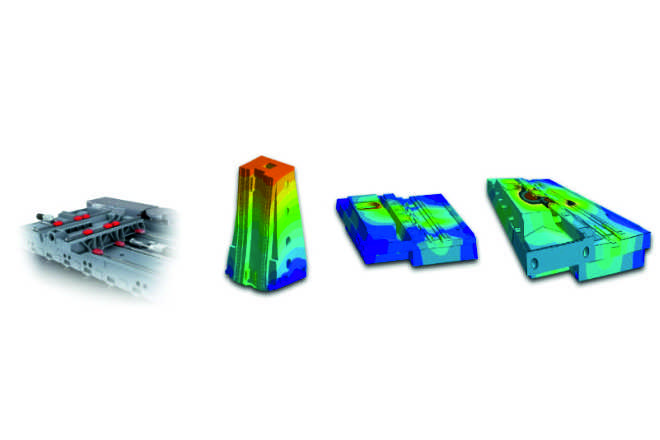

Reinforced Body Structure

- Wide span design of machine structure.

- High efficiency traveling column design.

- Large delta machine column and base ensure highest stability.

- With FEM analysis.

- With stepped design and 6 slider blocks on X-axis ensure the ultra reliable axial movement.

Reinforced Body Structure

- Wide span design of machine structure.

- High efficiency traveling column design.

- Large delta machine column and base ensure highest stability.

- With FEM analysis.

- With stepped design and 6 slider blocks on X-axis ensure the ultra reliable axial movement.

High Performance

- Large working area is ideal for large and long workpieces machining.

- With the installation of piding wall in the working area, both long and complex parts can be manufactured in the same machine.

High Efficiency

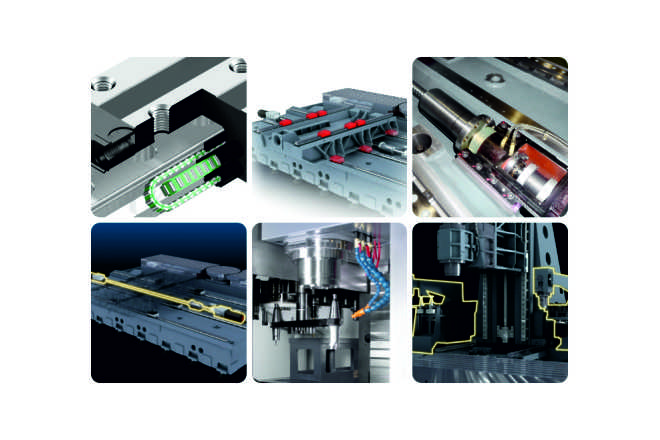

- High precision roller type guideways on 3 axes

- Capable of reaching up to 40 m/min rapid feedrate.

- Circulated cooling system design on X-axis ensures stable temperature and optimal accuracy.

- Centroid driven on X-axis to reduce vibration during movement.

- No counter weight design on Z-axis that lowers vibration while machining and greatly improves surface roughness.

- The guide blocks support tool magazine to ensure smooth and stable movement.

- Reliable ATC system: Tool magazine with 40T. (80T opt.)

High Efficiency

- High precision roller type guideways on 3 axes

- Capable of reaching up to 40 m/min rapid feedrate.

- Circulated cooling system design on X-axis ensures stable temperature and optimal accuracy.

- Centroid driven on X-axis to reduce vibration during movement.

- No counter weight design on Z-axis that lowers vibration while machining and greatly improves surface roughness.

- The guide blocks support tool magazine to ensure smooth and stable movement.

- Reliable ATC system: Tool magazine with 40T. (80T opt.)

Low backlash swivel head and rotary table

- Max. speed (B-axis): 33.3 rpm

- Swivel angle (B-axis): ±110° / ±120° (Big torque opt.)

- Max. speed (C-axis): 50 rpm (FANUC opt.) / 90 rpm (HEIDENHAIN std.)

- Positioning accuracy (C-axis): <10 sec.

YCM In-House Built-in Spindle

- The YCM in-house built-in spindle effectively lowers vibration, providing the best surface performance. Meanwhile, it prolongs lifespan of spindle and tools during heavy cutting.

- BBT40 double contact spindle taper greatly enhances machining accuracy.

- Up to 16,000 rpm spindle, 50 kW 67 HP outputs and Swivel angle 120°, best for heavy cutting. (opt.)

- Tool shank: HSK A63 (opt.)

YCM In-House Built-in Spindle

- The YCM in-house built-in spindle effectively lowers vibration, providing the best surface performance. Meanwhile, it prolongs lifespan of spindle and tools during heavy cutting.

- BBT40 double contact spindle taper greatly enhances machining accuracy.

- Up to 16,000 rpm spindle, 50 kW 67 HP outputs and Swivel angle 120°, best for heavy cutting. (opt.)

- Tool shank: HSK A63 (opt.)