A61NX

Makino 3-Axis CNC HMC Machine A61NX

Pallet - 500x500

Pallet

500x500

Travel(XxYxZ)(mm)

730x650x800

Spindle

BT50 (HSK-A63)

SPECIFICATION

A61NX

Unit

Values

Spindle

Makino Spindles are best in the global competitive market.

The heart of Makino machines is the spindle, which distinguishes them through features such as lower power consumption, improved surface quality, and minimized vibrations.

Master-crafted spindles

Each spindle is dedicated to specific machines, ensuring that they are meticulously engineered to deliver optimal performance for their respective applications.

Spindle

Makino Spindles are best in the global competitive market.

The heart of Makino machines is the spindle, which distinguishes them through features such as lower power consumption, improved surface quality, and minimized vibrations.

Master-crafted spindles

Each spindle is dedicated to specific machines, ensuring that they are meticulously engineered to deliver optimal performance for their respective applications.

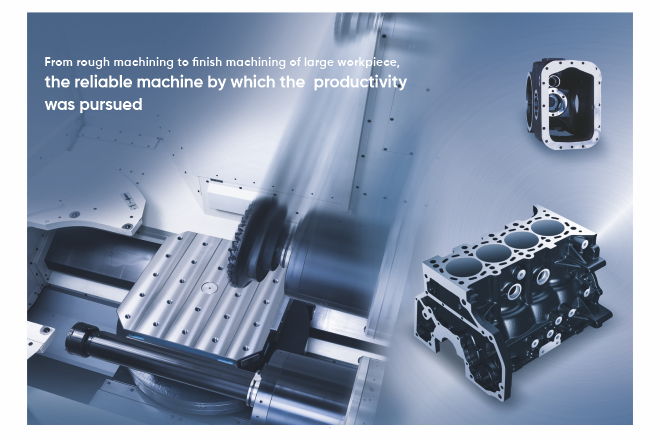

- From Rough machining to finish

- From Rough machining to finish machining of larger workpiece

- The reliable machine by which the productivity was pursued

- Reduce non cutting time and enhance productivity

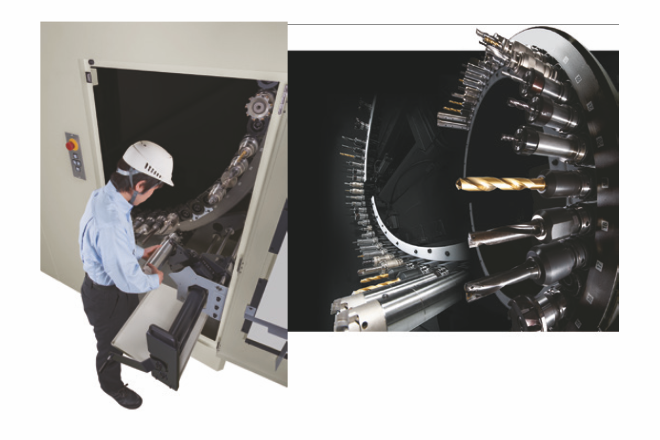

- High acceleration feed axis mechanism and reduce indexing time

- Shorter time to change tool

- Tool Preparation time: 5sec

- ATC Shutter can synchronize the opening distance to match the tool lengths

- Tool to Tool:1.7sec

- High Speed ring type tool magazine

- Tool storage capacity:60

- An inertia adaptive control is also adopted in the ring magazine. By automatically grasping the tool total weight, the tool preparation time could be attained 5 sec as well as being increased the response

- Large capacity matrix magazine

- Tool storage capacity: 136

- Shorter time to change tool

- Tool Preparation time: 5sec

- ATC Shutter can synchronize the opening distance to match the tool lengths

- Tool to Tool:1.7sec

- High Speed ring type tool magazine

- Tool storage capacity:60

- An inertia adaptive control is also adopted in the ring magazine. By automatically grasping the tool total weight, the tool preparation time could be attained 5 sec as well as being increased the response

- Large capacity matrix magazine

- Tool storage capacity: 136

Professional 6

- Control Unit that maximises machine performance

- Optimizes its machining operation according to machining condition.

- Even a machine is operated at high speed and high acceleration, it enables to maintain machined surface quality and shape accuracy, which in turn increase machining efficiency.

- By making proper use of the machining modes, productivity can be further improved

Chip Evacuation System

- Large volumes of chips in various sizes are evacuated quickly and effectively

- High productive machining centers generate large volumes of chips.

- To ensure efficient and reliable chip removal, the machining envelope is composed almost entirely of the slanted panels.

- Coolant from the spindle head and ceiling of the guard flush the chips directly into the center trough under the table.

- Large volume base coolant in the center trough washes the chips towards the lift up chip conveyor.

- Spindle head washing coolant nozzle for chip removal from spindle top

Chip Evacuation System

- Large volumes of chips in various sizes are evacuated quickly and effectively

- High productive machining centers generate large volumes of chips.

- To ensure efficient and reliable chip removal, the machining envelope is composed almost entirely of the slanted panels.

- Coolant from the spindle head and ceiling of the guard flush the chips directly into the center trough under the table.

- Large volume base coolant in the center trough washes the chips towards the lift up chip conveyor.

- Spindle head washing coolant nozzle for chip removal from spindle top