VG500

EXCETEK CNC Wire EDM VG500

EXCETEK CNC Wire EDM VG500are Finest CNC Wire EDM Machines With Excellent Precision And Reliability.

Travel

Travel - (X,Y)/(U,V)/Z - 500*300/80 * 80/220

Axes Control

Axes Control - 5 Axis AC Servo Motor

SPECIFICATION

VG500

Unit

Values

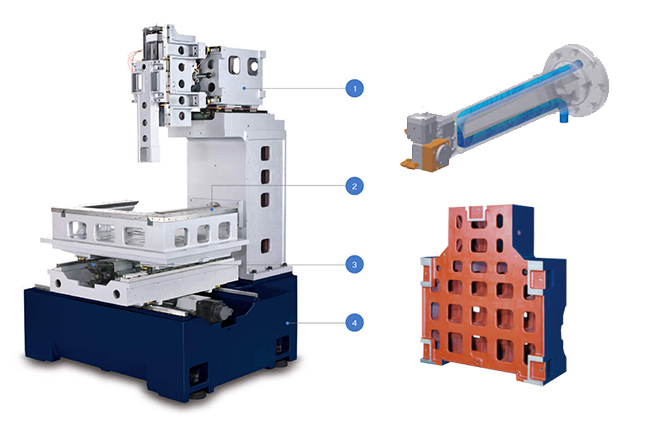

Machine feature

- Rigid U, V truss design

- Stainless steel worktable with hardness HRC 50°.

- Machine Casting is designed based on the FEA analysis for increasing the rigidity.

- Machine base with extra wide.

To ensure thermal balance, RIB location is designed by finite element analysis (FEA)assuring and optimized rigid structure.

Water cooled lower arm prevents thermal expansion caused by heat buildup. Therefore the accuracy will be improved.

A rugged cast iron machine structure is the foundation of precision.

Machine feature

- Rigid U, V truss design

- Stainless steel worktable with hardness HRC 50°.

- Machine Casting is designed based on the FEA analysis for increasing the rigidity.

- Machine base with extra wide.

To ensure thermal balance, RIB location is designed by finite element analysis (FEA)assuring and optimized rigid structure.

Water cooled lower arm prevents thermal expansion caused by heat buildup. Therefore the accuracy will be improved.

A rugged cast iron machine structure is the foundation of precision.

Intelligent machining mode

Workpiece postioning function - https://www.excetek.com/images/im2.jpg

Maintenance and Diagnosis information - https://www.excetek.com/images/im3.jpg

Technology data search function - https://www.excetek.com/images/im4.jpg

Graphical interface - https://www.excetek.com/images/im5.jpg

Useful function - https://www.excetek.com/images/im6.jpg

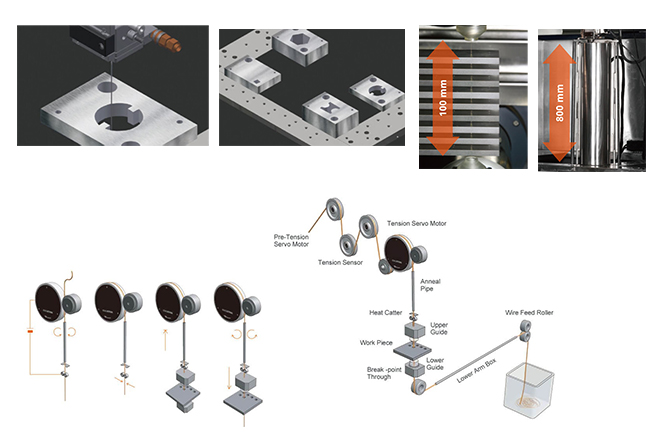

Automatic Wire Threading

Continout unmanned operation day night, nonstop machining with ideal break point automatic wire threading.

Automatic Wire Threading

- Unnecessary to pay attention to wire bread; reduction of the operation cost.

- The multi-jobs machining would be much easier since the machining will be automatically finished without manual command.

- G54~59 coordinate can be utilized for automatic work-piece change.

Automatic Wire Threading

Threading at the wire break point. Annealing is used to improve the straightness of the wore. The wire can be threaded at the break point during machining, with virtually 100% reliability and without the need to return to the start hole.

Submeraged Wire Threading : Wire threading is also easy execute during submerged machining, saves time to drain and refill the work tank.

Multi-hole machining function : On the rare occasion events when the machine fails to rethread during multi-hole machining, the system will skip to the next hole. The location of the skipped hole is automatically stored in memory and can be recalled later to complete the machining.

High Speed Auto Wire Threading System

Workpiece Thickness 100mm

- Wire annealing and cutting : 10 sec

- Threading : 10 sec

- Workpiece Thickness 800mm

- Threading under the water at break point.

Reliable Auto Wire Threading system

The EXCETEK AWT is very sophisticated design that provides continuous unmanned operation day and night. Unlike other systems it can thread at the point of the wire breakage.

A water jet function enables the machine to thread workpieces up to 500mm.

Automatic Wire Threading

Continout unmanned operation day night, nonstop machining with ideal break point automatic wire threading.

Automatic Wire Threading

- Unnecessary to pay attention to wire bread; reduction of the operation cost.

- The multi-jobs machining would be much easier since the machining will be automatically finished without manual command.

- G54~59 coordinate can be utilized for automatic work-piece change.

Automatic Wire Threading

Threading at the wire break point. Annealing is used to improve the straightness of the wore. The wire can be threaded at the break point during machining, with virtually 100% reliability and without the need to return to the start hole.

Submeraged Wire Threading : Wire threading is also easy execute during submerged machining, saves time to drain and refill the work tank.

Multi-hole machining function : On the rare occasion events when the machine fails to rethread during multi-hole machining, the system will skip to the next hole. The location of the skipped hole is automatically stored in memory and can be recalled later to complete the machining.

High Speed Auto Wire Threading System

Workpiece Thickness 100mm

- Wire annealing and cutting : 10 sec

- Threading : 10 sec

- Workpiece Thickness 800mm

- Threading under the water at break point.

Reliable Auto Wire Threading system

The EXCETEK AWT is very sophisticated design that provides continuous unmanned operation day and night. Unlike other systems it can thread at the point of the wire breakage.

A water jet function enables the machine to thread workpieces up to 500mm.

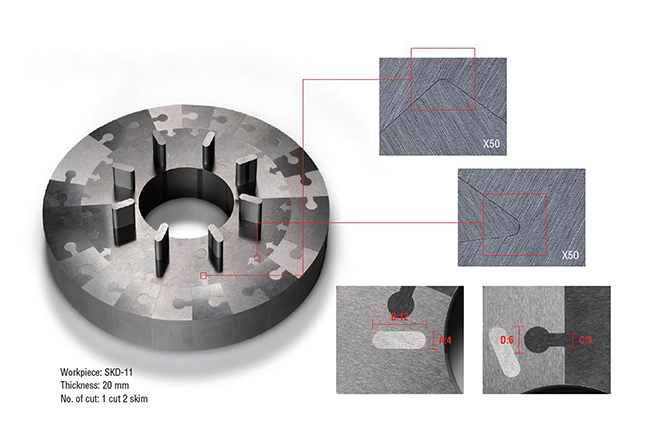

Cutting Technology

Type | Without control | Using control |

A | 0 | 0 |

B | 0 ~ -2 µm | -8 ~ -10 µm |

C | 0 | 0 |

D | 0 ~ -2 µm | -8 ~ -10 µm |

Remote Monitor System

https://www.excetek.com/images/rms1.jpg

Remote Monitor System

https://www.excetek.com/images/rms1.jpg