NP400L

EXCETEK CNC Wire EDM NP400L

EXCETEK CNC Wire EDM NP400L Are Finest CNC Wire EDM Machines With Excellent Precision And Reliability.

Travel

Travel - (X,Y)/(U,V)/Z - 400*300/80 * 80/220

Axes Control

Axes Control - XY Axis Linear Motor, UV Z Axis AC Servo Motor

Machine Dimension

Machine Dimension - 2260 X 2525 X 2100

SPECIFICATION

NP400L

Unit

Values

Intelligent machining mode

- https://www.excetek.com/images/im2.jpg

- https://www.excetek.com/images/im3.jpg

- https://www.excetek.com/images/im4.jpg

- https://www.excetek.com/images/im5.jpg

- https://www.excetek.com/images/im6.jpg

Intelligent machining mode

- https://www.excetek.com/images/im2.jpg

- https://www.excetek.com/images/im3.jpg

- https://www.excetek.com/images/im4.jpg

- https://www.excetek.com/images/im5.jpg

- https://www.excetek.com/images/im6.jpg

Auto wire threading

200mm Submerge threading - https://www.excetek.com/images/aw7.jpg

200mm Submerge threading - https://www.excetek.com/images/aw8.jpg

400mm thickness threading in break point - https://www.excetek.com/images/aw9.jpg

High Speed Auto Wire Threading System

Workpiece thickness 100mm

- Wire annealing and cutting : 10 sec

- Threading : 10 sec

Reliable Auto Wire Threading system

In EXCETEK, AWT provides a sophisticated design which generates continuous unmanned operation for 24 hours. Unlike other systems it can thread from the point of the wire breakage or break point.

A water jet function enables the machine to thread workpieces up to 500mm.

On-line measurement system

CBefore the machining, on-line measurement and calibration instead of the conventional one, significantly reduce the time to calibrate the workpiece. With the macro command the automatic measurement calibrates the reference point; enhance the machining accuracy. After machining, directly on-line measure the workpiece on the table; avoid the unexpected error from dismount/mount the workpiece.

Multi-workpiece machining

- Automatic compensating the 3D flatness of workpiece.

- Automatic compensating the parallelism of workpiece (AR)

- Automatic machining reference point measurement.

- Processing AWT automatic wire threading

- Go to the next workpiece to continue processing.

Processing automation

- Automatic compensating the parallelism of workpiece (AR)

- Automatically calibrate the reference point

- Processing AWT automatic wire threading

- Automatically measure the results after machining

- Export the measurement report

Automatic Measurement Application

- https://www.excetek.com/images/online3.jpg

- https://www.excetek.com/images/online4.jpg

- https://www.excetek.com/images/online5.jpg

- https://www.excetek.com/images/online6.jpg

- https://www.excetek.com/images/online8.jpg

- https://www.excetek.com/images/online9.jpg

- https://www.excetek.com/images/online10.jpg

On-line measurement system

CBefore the machining, on-line measurement and calibration instead of the conventional one, significantly reduce the time to calibrate the workpiece. With the macro command the automatic measurement calibrates the reference point; enhance the machining accuracy. After machining, directly on-line measure the workpiece on the table; avoid the unexpected error from dismount/mount the workpiece.

Multi-workpiece machining

- Automatic compensating the 3D flatness of workpiece.

- Automatic compensating the parallelism of workpiece (AR)

- Automatic machining reference point measurement.

- Processing AWT automatic wire threading

- Go to the next workpiece to continue processing.

Processing automation

- Automatic compensating the parallelism of workpiece (AR)

- Automatically calibrate the reference point

- Processing AWT automatic wire threading

- Automatically measure the results after machining

- Export the measurement report

Automatic Measurement Application

- https://www.excetek.com/images/online3.jpg

- https://www.excetek.com/images/online4.jpg

- https://www.excetek.com/images/online5.jpg

- https://www.excetek.com/images/online6.jpg

- https://www.excetek.com/images/online8.jpg

- https://www.excetek.com/images/online9.jpg

- https://www.excetek.com/images/online10.jpg

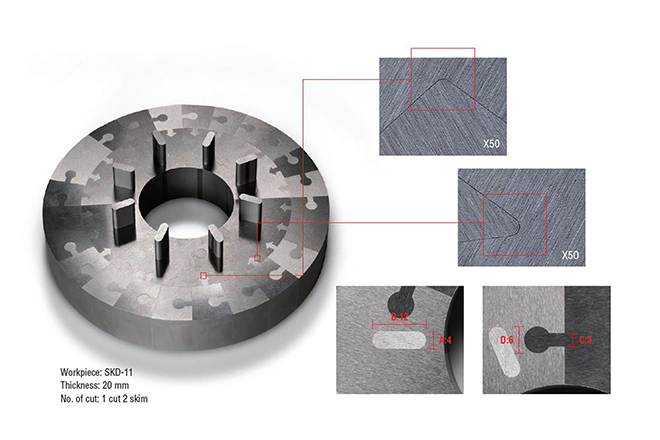

Cutting Technology

|

Type |

Without

control |

Using

control |

|

A |

0 |

0 |

|

B |

0 ~

-2 µm |

-8

~ -10 µm |

|

C |

0 |

0 |

|

D |

0 ~

-2 µm |

-8

~ -10 µm |

Remote Monitor System

https://www.excetek.com/images/rms1.jpg

Remote Monitor System

https://www.excetek.com/images/rms1.jpg