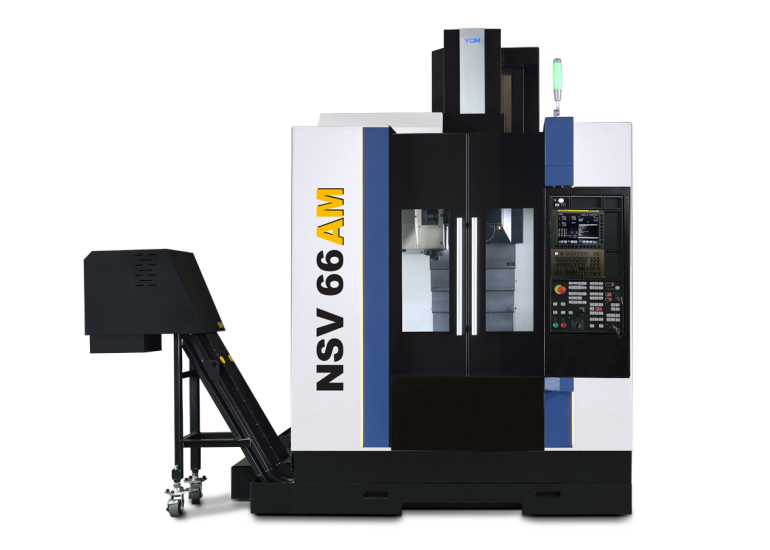

NSV66AM

YCM CNC Vertical Machining Center NSV66AM

S&T Engineers Is The Authorised Distributors Of YCM VMC Machines In India. YCM High Precision And Reliable NSV Series Performance VMC Machines Well Suited For Best Surface Finish Applications. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 12,000 (15,000 / 20,000)Spindle Taper (Opt.) - BBT40

Travel

Travel(mm)(X-Y-Z) - 660-510-560

ATC

Tool Magazine Capacity (Opt.)(T) - 30

SPECIFICATION

NSV66AM

Unit

Values

Spindle Speed (Opt.)

Rpm

12,000 (15,000 / 20,000)

Spindle Power (Opt.)

KW

25(25/22)

Spindle Taper (Opt.)

BBT40

X-Axis Travel

Mm

660

Y-Axis Travel

Mm

510

Z-Axis Travel

Mm

560

Distance Between Spindle Nose & Table Top

Mm

100~660

Table Size

Mm

840 X 560

No. T-Slot X Size X Pitch

Mm

5 X 18 X 100

Max. Load On Table

Kg

500

X/Y/Z Rapid Feedrate

M/min.

24 / 24 / 24

Cutting Feedrate

Mm/min.

1~20,000

Tool Magazine Capacity (Opt.)

T

30

Tool Weight

Kg/pc

6

Max. Tool Dimension (W/O Adjacent Tools)

Mm

ø76 X 300 (ø125 X 300)

Machine Weight

Kg

6500

Isolated Direct Drive Spindle

- The unique IDD spindle with speed of 12,000 rpm / 15,000 rpm (opt.) and ceramic bearings offer low spindle vibration and optimal heat isolation.

- High performance spindle motor of 22 kW 30 HP output

- Result in excellent surface finish while maximizing both spindle and tool life under hard milling conditions.

Isolated Direct Drive Spindle

- The unique IDD spindle with speed of 12,000 rpm / 15,000 rpm (opt.) and ceramic bearings offer low spindle vibration and optimal heat isolation.

- High performance spindle motor of 22 kW 30 HP output

- Result in excellent surface finish while maximizing both spindle and tool life under hard milling conditions.

Built-in Motorized Spindle (Opt.)

- Maximum spindle speed: 20,000 rpm

- Superb spindle cooling system with YCM patent provides minimum spindle vibration.

- Rear bearing floating design

- Micro oil-air lubrication system

- BBT40 double contact spindle taper

High Rigidity Structural Design

- X/Y/Z axes equipped with the roller type linear guideways and large diameter ball screw that maximize aluminum chip disposal during processing

- Extra large delta machine column

- Double-nut ball screw with high performance axial servo motor

- Wide distance between guideways

- Advanced design with reinforced body structure through FEM analysis, the NSV series offers superb cutting performance and reduced vibration to meet the highest machining demand.

High Rigidity Structural Design

- X/Y/Z axes equipped with the roller type linear guideways and large diameter ball screw that maximize aluminum chip disposal during processing

- Extra large delta machine column

- Double-nut ball screw with high performance axial servo motor

- Wide distance between guideways

- Advanced design with reinforced body structure through FEM analysis, the NSV series offers superb cutting performance and reduced vibration to meet the highest machining demand.

Column Mounted Design

- Minimizes the vibration during tool change

- Tool magazine capacity: 30T

- Standard ATC door prevents coolant and chips from entering tool magazine.