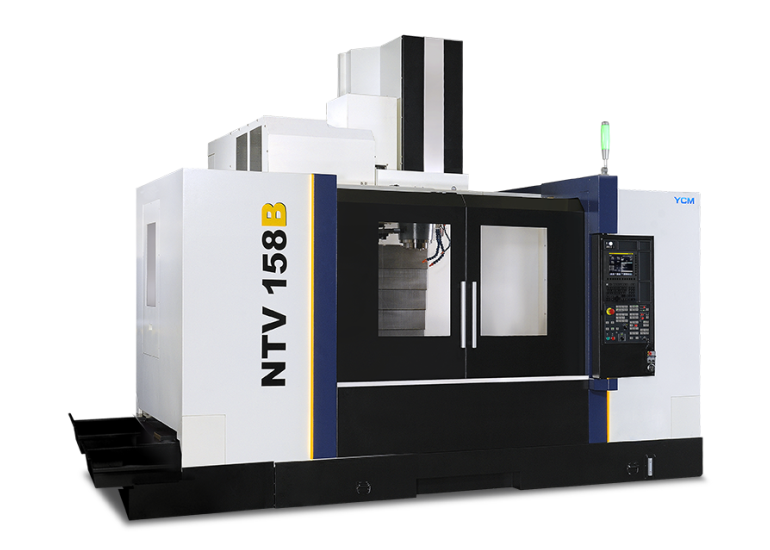

NTV158B

YCM CNC Vertical Machining Center NTV158B

S&T Engineers Is The Authorised Distributors Of YCM VMC Machines In India. YCM High Precision And Reliable NTV Series VMC Machine Suitable For Large Sized Die And Mould Machining. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 10,000 (15,000) Spindle Taper (Opt.) - BBT50(HSK-A100)

Travel

Travel(mm)(X-Y-Z) - 1530-762-700

ATC

Tool Magazine Capacity (Opt.)(T) - 24(32/40)

SPECIFICATION

NTV158B

Unit

Values

Spindle Speed (Opt.)

Rpm

10,000 (15,000)

Spindle Power (Opt.)

KW

22(30)

Spindle Taper (Opt.)

BBT50(HSK-A100)

X-Axis Travel

Mm

1530

Y-Axis Travel

Mm

762

Z-Axis Travel

Mm

700

Distance Between Spindle Nose & Table Top

Mm

200~900(450~1150)

Table Size

Mm

1,650 X 760

No. T-Slot X Size X Pitch

5 X 22 X 150

Max. Load On Table

Kg

2000

X/Y/Z Rapid Feedrate

M/min.

30/30/24

Cutting Feedrate

Mm/min.

1~10,000

Tool Magazine Capacity (Opt.)

T

24(32/40)

Tool Weight

Kg/pc

20

Max. Tool Dimension (W/O Adjacent Tools)

Mm

24T: ø110 X 350(ø190 X 350) 32T/40T: ø120 X 350(ø240 X 350)

Machine Weight

Kg

15500

Superb Body Structure

- With the unique T-base structure, the machine footprint can be reduced effectively.

- Overhang-free table movement is supported by high-rigidity base to ensure the best dynamic accuracy.

- Dual screw-type chip augers efficiently elevate chip removal rate.

- Massive MEEHANITE® casting through FEM analysis offers exceptional damping capacity.

Superb Body Structure

- With the unique T-base structure, the machine footprint can be reduced effectively.

- Overhang-free table movement is supported by high-rigidity base to ensure the best dynamic accuracy.

- Dual screw-type chip augers efficiently elevate chip removal rate.

- Massive MEEHANITE® casting through FEM analysis offers exceptional damping capacity.

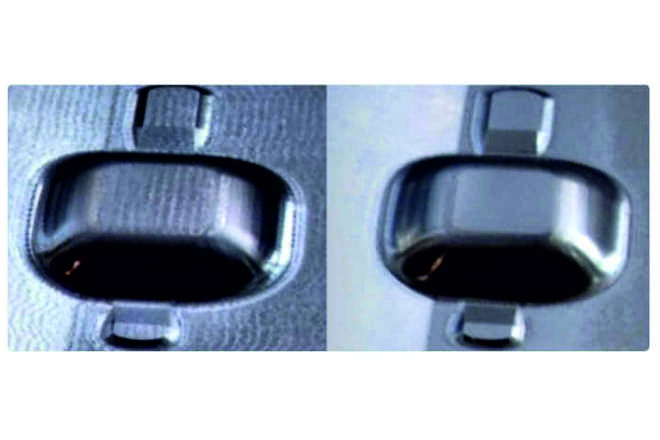

YCM In-house IDD Spindle

- Reduces noise, backlash and vibration issues and maximizes spindle accuracy and life.

- YCMs uniquely designed IDD Spindle ensures direct transmission and is proven to maximize both spindle and tool life under harsh working environment.

- The cooling system for spindle motor seat and spindle makes real time control of spindle temperature.

- The oil-air lubrication system ensures long-term high-speed operation.

Efficiency-friendly Design

- The casting rigidity is enhanced through FEM analysis.

- Roller type guideways provides low friction which reduces energy waste.

Efficiency-friendly Design

- The casting rigidity is enhanced through FEM analysis.

- Roller type guideways provides low friction which reduces energy waste.

Z-axis Dual Driven

- Increases the feedrate and acceleration/deceleration.

- High response axial control provide smooth movement.

- Low inertia avoids vibration during high speed feedrate.

- Dual drive system on Z-axis elevates exceptional axial smoothness and machining efficiency, and ensures fine surface roughness.

- Up to 15,000 rpm (HSK A100) spindle is available to meet different machining demands.