YCM I5

YCM Vertical Machining Center I5

"State Of The Art Technology In Mind Packed & Loaded With Additional Features. Rugged Meehanite Castings & Fem Analysis To Simulate The Structural Deformation & Chatter Free Cutting."

Highlight 1

1020x540x540

Highlight 2

10000/7.5-15kW/BBT40

Highlight 3

24 - ARM Type

SPECIFICATION

YCM I5

Unit

Values

Spindle Speed

Rpm

10,000

Spindle Power

KW

7.5 / 11 / 15 Kw 10 /15 / 20 HP ( Cont./6min/2.5min)

Spindle Taper

-

BBT40

X / Y / Z-Axis Travel

Mm

1,020 Mm / 520 Mm / 540mm 40.16" / 20.47'" / 21.26"

Distance Between Spindle Nose & Table Top

Mm

140 ~ 680 Mm 5.51" ~ 26.77"

Table Size

Mm

1,120 X 520 Mm 44" X 20.47"

No. T-Slot X Size X Pitch

Mm

5 X 18 Mm X 100 Mm 5 X 0.71" X 3.94"

Max. Load On Table

Kg

500kg 1,102 Ib

Rapid Feedrate(X/Y/Z)

M/min

36 / 36 / 24 M/min. 1,417 / 1,417 / 945 Ipm

Cutting Feedrate

Mm/min

1~20,000 Mm/min. 0.04 ~ 787 Ipm

Axial Travel

-

Full Length

Positioning (X / Y / Z) A

Mm

0.032 / 0.025 / 0.025 Mm | 0.01 / 0.01 / 0.01 Mm

Repeatability(X / Y / Z) R

Mm

0.018 / 0.015 / 0.015 Mm | 0.007 / 0.007 / 0.007 Mm

Max.Tool Weight (per Piece)

Kg

6kg 13.2 Ib

Max. Tool Dimensions(W/O Adjacent Tools)

-

∅80 X 300 Mm (∅140 X 300 Mm) ∅3.15" X 11.81" (∅5.51" X 11.81")

Tool Change Method

-

Arm Type

Tool Selection Method

-

Random

Pneumatic Supplier

Kg

5.5 Kg/cm² 78.2 Psi

Machine Weight

Kg

5,350 Kg 11,795 Ib

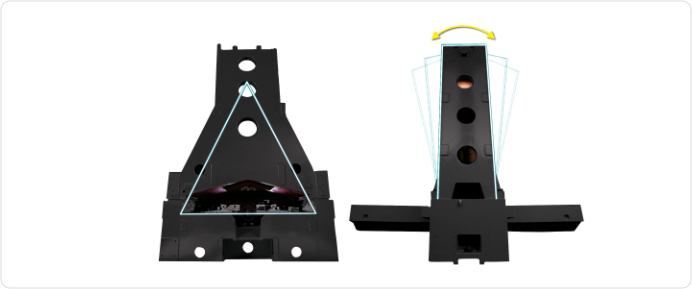

Structure

- High rigidity Dual-Wall castings.

- Auto oil lubrication system for all axis.

- High rigidity ball type linear guideways.

- Fanuc α-series 15kW powerful spindle motor.

- Fixed pretensioned, high precision ball screws.

- Powerful 3kW direct drive axis motors in all 3 axis.

- 10,000rpm spindle with cooling system and ceramic bearings.

- FEM technique enables superiors machining stable performance.

- Axial assembly supported by integrated structure, providing excellent dynamic movement

Structure

- High rigidity Dual-Wall castings.

- Auto oil lubrication system for all axis.

- High rigidity ball type linear guideways.

- Fanuc α-series 15kW powerful spindle motor.

- Fixed pretensioned, high precision ball screws.

- Powerful 3kW direct drive axis motors in all 3 axis.

- 10,000rpm spindle with cooling system and ceramic bearings.

- FEM technique enables superiors machining stable performance.

- Axial assembly supported by integrated structure, providing excellent dynamic movement