TC46M

YCM Turning Center TC46M

S&T Engineers Is The Authorised Distributors Of YCM Turning Center Machines In India. YCM High Precision And Reliable Box Type Guideway Turning Center Machines For High Productivity Application. Advanced Taiwanese CNC Machining Technology In India At Best Price

Machining Capacity

Max. Turning Diameter(mm) - ø730 Max. Turning Length(mm) - 3111

Main Spindle

Chuck Size - 15" (18", 21")

Tailstock

Quill Taper - MT-5 Quill Stroke(mm) - 3015

SPECIFICATION

TC46M

Unit

Values

Max. Turning Diameter

Mm

ø730

Max. Turning Length

Mm

3,111

Chuck Size

15" (18", 21")

Spindle Nose

A2-11

Hole Through Spindle

Mm

ø130

Hole Through Draw Bar

Mm

ø117

Spindle Speed

Rpm

1,800 Rpm (15") / 1,600 Rpm (18") / 1,200 Rpm (21")

C-Axis Speed

Rpm

50

X-Axis Travel

Mm

415 (365+50)

Z-Axis Travel

Mm

3,200

"X - Axis Rapid Feedrate / Cutting Feedrate"

M/min / Mm/min

16 / 1~10,000

"Z - Axis Rapid Feedrate / Cutting Feedrate"

M/min / Mm/min

12 / 1~10,000

Main Spindle Motor

KW

30 / 37

Turret Type

Radial Power Turret (Servo Rotation, Hydraulic Clamping)

Turret Capacity (opt.)

12T(BMT85)

Live Tool Motor Speed

Rpm

100~3,000

Live Tool Motor Torque

Kgf-m

16

Swing Over Turret

Mm

ø890

Quill Taper

MT-5

Quill Stroke

Mm

3,015

Machine Weight

Kg

15,500

Efficient Chip Disposal System

- With slanted design and superb chip removal space under the spindle, it is more easier to clean chips.

- High pressure coolant is supplied for optimal chip removal.

- Shower coolant from the roof removes the chips from the chuck and telescopic guideway cover. (opt.)

Efficient Chip Disposal System

- With slanted design and superb chip removal space under the spindle, it is more easier to clean chips.

- High pressure coolant is supplied for optimal chip removal.

- Shower coolant from the roof removes the chips from the chuck and telescopic guideway cover. (opt.)

Programmable tail stock

- MT-5 fixed quill with live center is standard, high rigidity rotary quill with dead center is optional.

- Tail stock using dual cylinder to clamp the guideways for prevent tail stock skid during machining. Using hydraulic connect bar to link the tail stock and carriage during tail stock positioning to save effort and time.

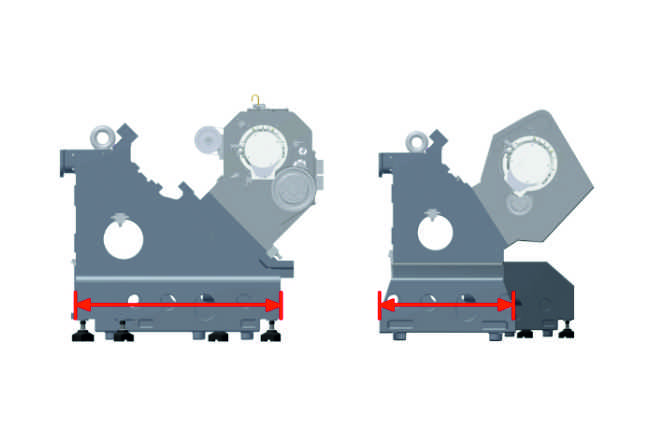

Rigid Structure Design

- MEEHANITE® casting frame through FEM analysis for one piece torque tube and 45 degree slant bed ensures the best rigidity and eliminates casting distortion.

- Z-axis design with an extra wide distance o f 620mm between guideways offers the highest rigidity.

- The box way base of 950mm is suitable for heavy duty machining and powerful chip removal.

Central Lubrication System

- The slide ways of X/Z-axis and ball screws are lubricated. Built-in alarm will be occurred when the lubrication oil is insufficient.

Rigid Structure Design

- MEEHANITE® casting frame through FEM analysis for one piece torque tube and 45 degree slant bed ensures the best rigidity and eliminates casting distortion.

- Z-axis design with an extra wide distance o f 620mm between guideways offers the highest rigidity.

- The box way base of 950mm is suitable for heavy duty machining and powerful chip removal.

Central Lubrication System

- The slide ways of X/Z-axis and ball screws are lubricated. Built-in alarm will be occurred when the lubrication oil is insufficient.

The Extra Large Front Bearing

- The extra large front bearing internaldiameter is ø180 mm to ensure the heavy duty cutting capability.

- Max. hole through spindle diameter is ø130 mm.

- Max. hole through draw bar is ø117 mm.

Fast & Reliable Motorized Turret

- 12 tools capacity with BMT 85 tooling system.

- Max. live tool power 15/18.5/22 kW 20/25/30 HP with Max. speed 3,000 rpm.

- Servo drive turret for high speed index.

- Hydraulic clamping turret with 3-piece large clutch for heavy duty cutting.

The Smoothest X-axis Movement and Prevents Turret Drop

- The hydraulic balance cylinder on X-axis ensures the smoothest axial movement and brake system prevents the turret from dropping when the power is suddenly off.

- With the double nuts design, the ball screws on the X/Z-axis provide the highest rigidity.

- The optional safety clutch will disassemble the ball screw from motor to protect the ball screw during a crash.

The Smoothest X-axis Movement and Prevents Turret Drop

- The hydraulic balance cylinder on X-axis ensures the smoothest axial movement and brake system prevents the turret from dropping when the power is suddenly off.

- With the double nuts design, the ball screws on the X/Z-axis provide the highest rigidity.

- The optional safety clutch will disassemble the ball screw from motor to protect the ball screw during a crash.