NFX400A

YCM 5-Axis Machining Center NFX400A

S&T Engineers Is The Authorised Distributors Of YCM 5-Axis VMC Machines In India. YCM High Precision And Reliable NFX Series High Performance 5-Axis Machines For High Productivity Application. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 12,000 ( 12,000/15,000 ) Spindle Taper (Opt.) - BBT40

Travel

Travel(mm)(X-Y-Z(Opt.)) - 650-520-480

ATC

Tool Magazine Capacity (Opt.)(T) - 24 (30 / 40 / 60 )

SPECIFICATION

NFX400A

Unit

Values

Spindle Speed (Opt.)

Rpm

12,000 ( 12,000/15,000 )

Spindle Power (Opt.)

KW

18.5 ( 25/25 )

Spindle Taper (Opt.)

-

BBT40

X-Axis Travel

Mm

650

Y-Axis Travel

Mm

520

Z-Axis Trave (Opt.)

Mm

480

Distance Between Spindle Center And Table Top

Mm

70~550

A-Axis

Degree

150˚ ( 30˚/ -120˚)

C-Axis

Degree

360˚

Table Size

Mm

ø350

No. T-Slot X Size X Pitch

Mm

12

Max. Load On Table

Kg

200

X/Y/Z Rapid Feedrate

M/min

36/36/36

Cutting Feedrate

Mm/min

1~20,000

Tool Magazine Capacity (Opt.)

T

24 (30 / 40 / 60 )

Tool Weight

Kg/pc

6

Max. Tool Dimension (W/O Adjacent Tools)

Mm

ø125 X 280

Machine Weight

Kg

6200

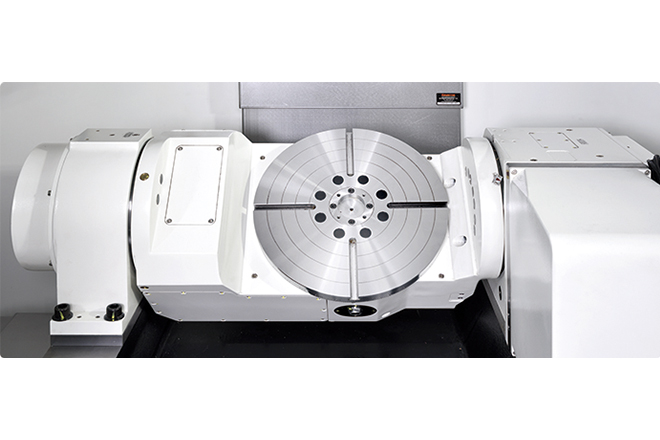

A/C-axis Rotary Table

- 150˚(+30˚/ -120˚) A-axis tilting angle increases the ability of machining.

- Rotary table surface is at the same level as the 5th axis centerline to ensure machining accuracy.

- ø350 mm (ø13.8") table size with ø50 mm (ø1.97") table-through hole design.

- Max. Workpiece Dimensions ø400 x 310 mm (ø15.8" x 12.2") .

- 6 Piping preparation for fixture (Air pressure x 2 + Hydraulic x 4).

A/C-axis Rotary Table

- 150˚(+30˚/ -120˚) A-axis tilting angle increases the ability of machining.

- Rotary table surface is at the same level as the 5th axis centerline to ensure machining accuracy.

- ø350 mm (ø13.8") table size with ø50 mm (ø1.97") table-through hole design.

- Max. Workpiece Dimensions ø400 x 310 mm (ø15.8" x 12.2") .

- 6 Piping preparation for fixture (Air pressure x 2 + Hydraulic x 4).

Tool Magazine

- 24T (30T opt.) Disk Type.

- 40 / 60 / 90 / 120T (opt.) Chain Type.

- ATC door design is standard that prevents coolant and chips from entering tool magazine.

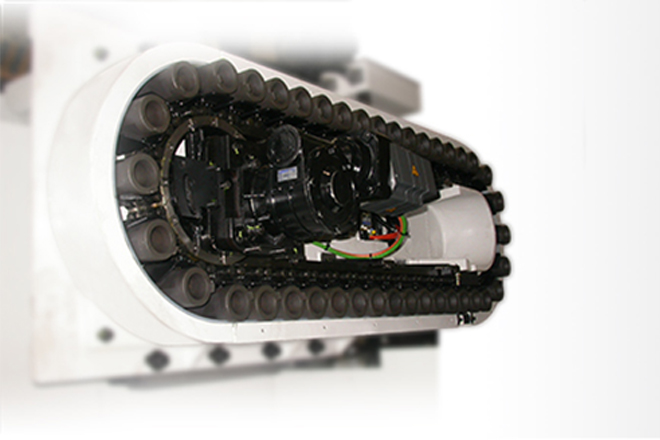

YCM In-house IDD PLUS Spindle

- YCM self-manufactured 12,000 rpm IDD PLUS spindle.

- Max. Spindle Power 22 kW, 15,000 rpm spindle (opt.) for hi-power, hi-speed machining.

- Cooling system design on spindle motor seat, quill, and bearing offers most reliable machining capability.

- Micro Oil-air Lubrication System (opt.)

- Reliable Helical Disc Spring

- Simultaneous Taper & Flange Contact Design

- BBT40 Spindle Design with spindle and taper dual surface contact ensures longer tool life, and exceptional cutting rigidity with high accuracy.

YCM In-house IDD PLUS Spindle

- YCM self-manufactured 12,000 rpm IDD PLUS spindle.

- Max. Spindle Power 22 kW, 15,000 rpm spindle (opt.) for hi-power, hi-speed machining.

- Cooling system design on spindle motor seat, quill, and bearing offers most reliable machining capability.

- Micro Oil-air Lubrication System (opt.)

- Reliable Helical Disc Spring

- Simultaneous Taper & Flange Contact Design

- BBT40 Spindle Design with spindle and taper dual surface contact ensures longer tool life, and exceptional cutting rigidity with high accuracy.

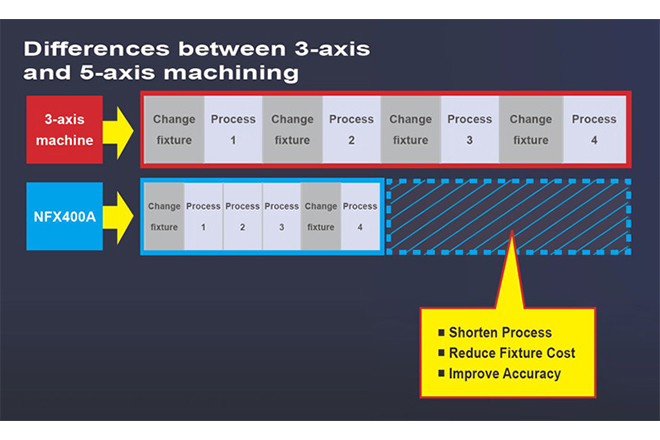

Advantages of 5-axis Machining

- Enhance precision, quality and efficiency of 3D surface machining.

- Reduce tool length and increase rigidity to obtain superior machining quality.

- Cutting with the belly and edge of the tool to increase tool life.

- Reduce fixture error and lessen workpiece loading/uploading time.

- Saves manufacturing cost for fixture and electrode costs.

- Reduces machining process, machining cost while improving productivity.