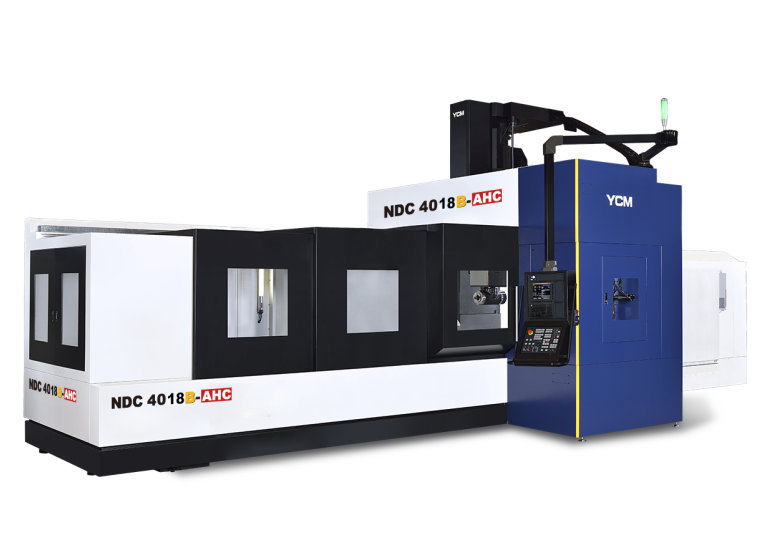

NDC4018B-AHC

YCM Double Column Machining Center NDC4018B-AHC

S&T Engineers Is The Authorised Distributors Of YCM Double Column VMC Machines In India. YCM High Precision And Reliable Auto Head Changing NDC Series Double Column Vmc Machines For High Productivity Application. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 6000 Spindle Taper (Opt.) - BBT50

Travel

Travel(mm)(X-Y-Z(Opt.)) - 4200-2200-762(1016)

ATC

Tool Magazine Capacity (Opt.)(T) - 40 (60)

SPECIFICATION

NDC4018B-AHC

Unit

Values

Spindle Speed (Opt.)

Rpm

6,000

Spindle Power (Opt.)

KW

35

Spindle Taper (Opt.)

BBT50

X-Axis Travel

Mm

4,200

Y-Axis Travel

Mm

2,200

Z-Axis Travel(Opt.)

Mm

762(1,016)

Distance Between Spindle Nose & Table Top

Mm

Vertical:500~1,262 Horizontal : 130~892[30"Standard] Vertical:750~1,512 Horizontal : 380~1,142 [30"Raised 250] Vertical:500~1,516 Horizontal : 130~1,146[40"Raised 250]

Distance Between Columns

Mm

1,800

Table Size

Mm

4,000×1,500

No. T-Slot X Size X Pitch

Mm

8 X 22 X 180

Max. Load On Table

Kg

12,000

X/Y/Z Rapid Feedrate

M/min.

15 / 20 / 15

Cutting Feedrate

Mm/min.

1~10,000

Tool Magazine Capacity (Opt.)

T

40 (60)

Tool Weight

Kg/pc

20

Max. Tool Dimension (W/O Adjacent Tools)

Mm

ø125 X 350(ø240 X 350)

Machine Weight

Kg

36,000

High Rigidity 90°Angle Head

- Self-manufactured gearbox provides high torque for both vertical and horizontal machining

- High rigidity octagonal milling head design

- Quiet precision grounded bevel gear, adopts oil-mist lubrication to reduce heat

- Large diameter toothed clutches provide high machining stability, precision and rigidity

- 4 independent pull studs with high clamping force

- 90°angle head anti-drop safety mechanism

- Optional coolant through spindle (CTS) for both vertical/ 90°angle head

High Rigidity 90°Angle Head

- Self-manufactured gearbox provides high torque for both vertical and horizontal machining

- High rigidity octagonal milling head design

- Quiet precision grounded bevel gear, adopts oil-mist lubrication to reduce heat

- Large diameter toothed clutches provide high machining stability, precision and rigidity

- 4 independent pull studs with high clamping force

- 90°angle head anti-drop safety mechanism

- Optional coolant through spindle (CTS) for both vertical/ 90°angle head