NXV1270A

YCM CNC Vertical Machining Center NXV1270A

S&T Engineers Is The Authorised Distributors Of YCM VMC Machines In India. YCM High Precision And Reliable NXV Series VMC Specially Crafted For High Productivity Applications. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - 12,000(15,000)Spindle Taper (Opt.) - BBT40

Travel

Travel(mm)(X-Y-Z) - 1270-660-620

ATC

Tool Magazine Capacity (Opt.)(T) - 24 (30/48/60)

SPECIFICATION

NXV1270A

Unit

Values

Spindle Speed (Opt.)

Rpm

12,000(15,000)

Spindle Power (Opt.)

KW

18.5(18.5)

Spindle Taper (Opt.)

BBT40

X-Axis Travel

Mm

1270

Y-Axis Travel

Mm

660

Z-Axis Travel

Mm

620

Distance Between Spindle Nose & Table Top

Mm

70 X 690 (320 X 940 )

Table Size

Mm

1,350 X 660

No. T-Slot X Size X Pitch

6 X 18 X 100

Max. Load On Table

Kg

1500

X/Y/Z Rapid Feedrate

M/min.

36/36/30

Cutting Feedrate

Mm/min.

1~20,000

Tool Magazine Capacity (Opt.)

T

24 (30/48/60)

Tool Weight

Kg/pc

6

Max. Tool Dimension (W/O Adjacent Tools)

Mm

24T : ø90 X 300 (ø140 X 300) 30T/48T/60T : ø76 X 300 (ø125 X 300)

Machine Weight

Kg

8600

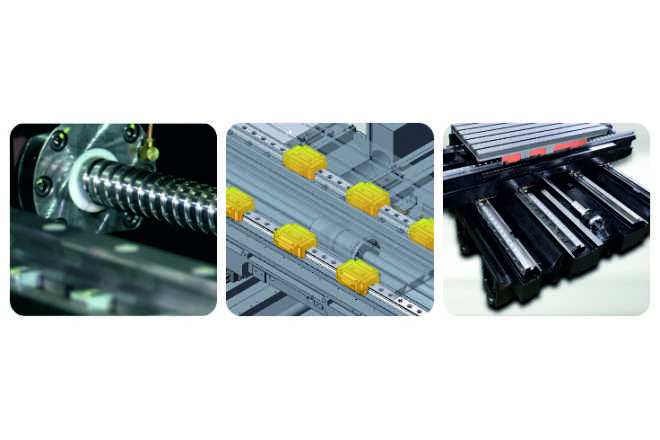

- FEM analysis is adopted to ensure the best mass arrangement and rib construction of the machine for constant stability under the intensive load of heavy-duty cutting.

- All axial AC servo motors equipped with Absolute Positioning Encoders, no zero return needed

- Direct drive provides backlash free, best accuracy, reliability and stability.

- Robust roller linear guideways applied on 3 axes.

- 6 blocks design on X-axis can easily support workpieces weighing up to 1,500 kg.

- 4-linear guideways on Y-axis with superior large span ensures the best dynamic balance.

- Rigid dual-wall castings on saddle

- Wide base structure with 10 leveling pads.

- The compact structure enables excellent floor space utilization

- FEM analysis is adopted to ensure the best mass arrangement and rib construction of the machine for constant stability under the intensive load of heavy-duty cutting.

- All axial AC servo motors equipped with Absolute Positioning Encoders, no zero return needed

- Direct drive provides backlash free, best accuracy, reliability and stability.

- Robust roller linear guideways applied on 3 axes.

- 6 blocks design on X-axis can easily support workpieces weighing up to 1,500 kg.

- 4-linear guideways on Y-axis with superior large span ensures the best dynamic balance.

- Rigid dual-wall castings on saddle

- Wide base structure with 10 leveling pads.

- The compact structure enables excellent floor space utilization

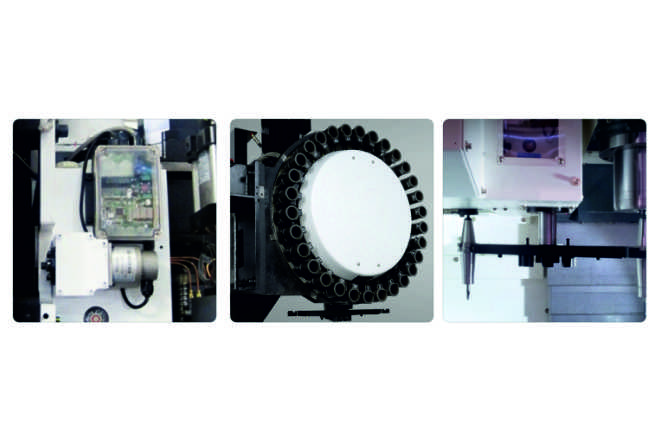

IDD Spindle Design: HIGH PRECISION HIGH SPEED

- The unique IDD spindle design offers smooth reliability at high speed.

- Ceramic bearings do not just boost the spindle speed, but also achieve high axial and radial rigidity, which fulfill strict machining requirements on heavy cutting, drilling and tapping.

High Stability Tool Magazine

- Absolute encoder ATC system provides high stability and speed.

- Inverter controlled, prevents tool change speed from changing under different power supply frequency.

- Tool change speed can be adjustable for heavy tools.

- Auto Tool Change (T-T): 1.8 sec.

- Tool Magazine Capacity: 24T (30T/48T/60T opt.)

High Stability Tool Magazine

- Absolute encoder ATC system provides high stability and speed.

- Inverter controlled, prevents tool change speed from changing under different power supply frequency.

- Tool change speed can be adjustable for heavy tools.

- Auto Tool Change (T-T): 1.8 sec.

- Tool Magazine Capacity: 24T (30T/48T/60T opt.)

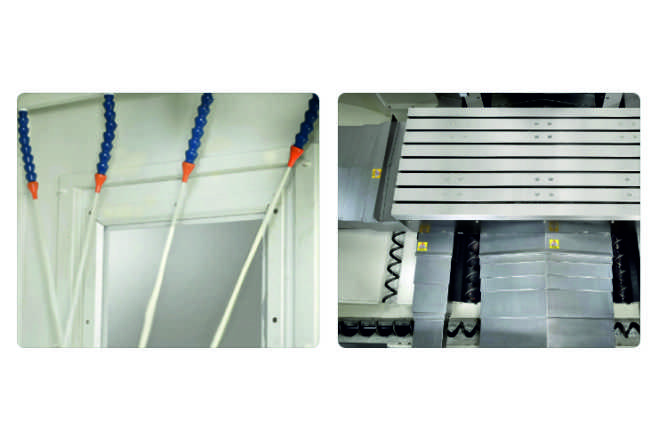

Automatic Tool Magazine Door Design

- Driven by pneumatic cylinder.

- Prevent coolant and chips from entering tool magazine.

Brand New Exterior Design

- Full enclosure exterior (including top cover).

- Convertible side window for convenient chip removal.

- Aesthetic rear cover design.

- Coolant shower for efficient chip removal <NXV Series std.>

- Penta chip augers (4 Y-axial 1 X-axial) ensure fluent chip removal prevent chips from piling up. [Quad chip augers (4 Y-axial Chip Conveyor) opt.]

Brand New Exterior Design

- Full enclosure exterior (including top cover).

- Convertible side window for convenient chip removal.

- Aesthetic rear cover design.

- Coolant shower for efficient chip removal <NXV Series std.>

- Penta chip augers (4 Y-axial 1 X-axial) ensure fluent chip removal prevent chips from piling up. [Quad chip augers (4 Y-axial Chip Conveyor) opt.]