SKCNC250T4000

SKITEK CNC Hydraulic Bending Machine SKCNC250T4000

Skitek 3-Axis CNC Press Brakes Machines Uses The Latest Technology To Offer High Quality Precision And Excellent Performance. The Hydraulic Systems In The Bending Machines Are More Advanced, Delivering Consistent Performance.

Bending Force(kN)

2500

Bending Length(mm)

4000

Dimension(LxWxH(mm))

4500x1800x2800

SPECIFICATION

SKCNC250T4000

Unit

Values

- Overall welded and processed structure.

- Closed loop control mode composed of electric-hydraulic servo valve and measure ruler.

- Ensures highest control precision and highest levels of press brake accuracy and repositioning accuracy.

- Integrated hydraulic system decreases the pipe connections, oil leakage, and increases the stability.

- Overall welded and processed structure.

- Closed loop control mode composed of electric-hydraulic servo valve and measure ruler.

- Ensures highest control precision and highest levels of press brake accuracy and repositioning accuracy.

- Integrated hydraulic system decreases the pipe connections, oil leakage, and increases the stability.

SKITEK backgauge mechanism can be multi-axes controlled

Backgauge

- The high precision backgauge device equipped with Hiwin ball screw and linear guide rail (Taiwan), adopts horizontal shell installation structure with high reliability, and single-shell double linear guide rails with high precision X-axis drive.

Worktable equipped with hydraulic and mechanical compensation to avoid the deformed upper beam from affecting the quality of the work piece. It is automatically adjusted by the CNC controller with convenience and accuracy

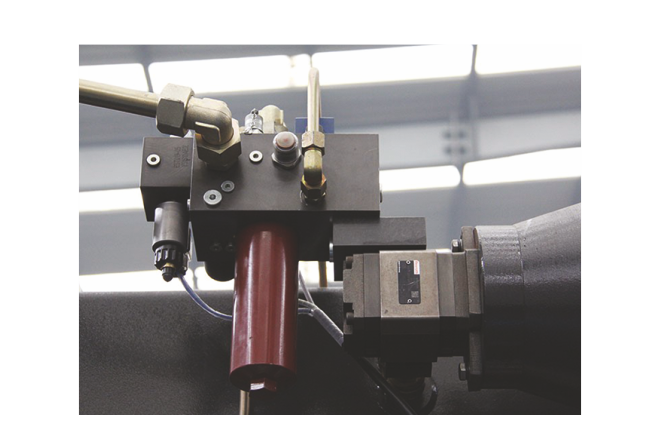

Hydraulic System

- Using valves and pumps manufactured by Germany’s Bosch Rexroth improves dependability and minimizes maintenance.

- It also ensures low sensitivity to oil pollution and increases durability.

Worktable equipped with hydraulic and mechanical compensation to avoid the deformed upper beam from affecting the quality of the work piece. It is automatically adjusted by the CNC controller with convenience and accuracy

Hydraulic System

- Using valves and pumps manufactured by Germany’s Bosch Rexroth improves dependability and minimizes maintenance.

- It also ensures low sensitivity to oil pollution and increases durability.

Electrical System

- The electrical components are manufactured by Schneider which offers greater reliability in conditions where power is unstable.

- These electrical components can be readily replaced anywhere in the globe.

Main Motor

- The CNC press brake machine’s motor is manufactured by the renowned German firm Siemens.

- This motor makes the machine more durable and quieter.

Main Motor

- The CNC press brake machine’s motor is manufactured by the renowned German firm Siemens.

- This motor makes the machine more durable and quieter.

Punch & Die/Fast clamping

- Standard double-V lower dies offer a wide range of slot sizes and shapes to choose from, easy die exchange, normal plate Press Brake capability, and an excellent price-to performance ratio.

- 42CrMo steel dies, with a hardness of 42 degrees after heat treatment, guarantees longer life.

- A fast clamp will make it easy to change the top punch swiftly and easily.