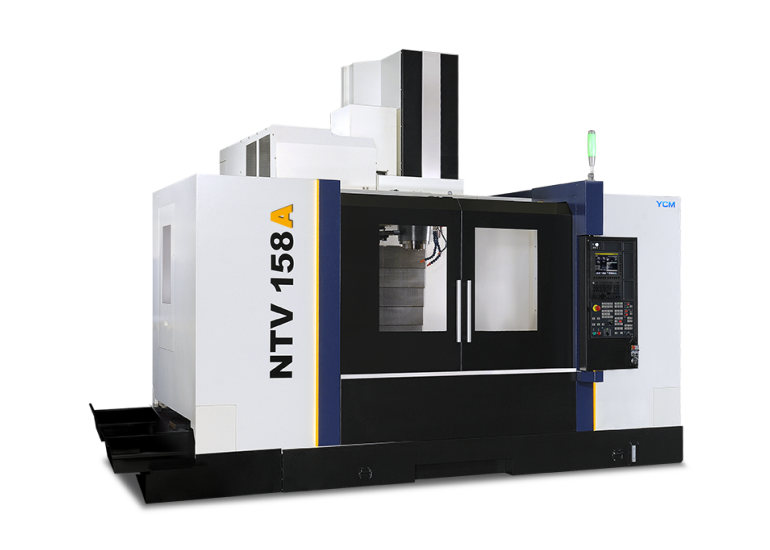

NDC3016B

YCM Double Column Machining Center NDC3016B

S&T Engineers Is The Authorised Distributors Of YCM Double Column VMC Machines In India. YCM High Precision And Reliable NDC Series Double Column Vmc Machines For High Productivity Application. Advanced Taiwanese CNC Machining Technology In India At Best Price

Spindle

Spindle Speed (Opt.)(rpm) - GB: 6,000 (IDD: 10,000) Spindle Taper (Opt.) - BBT50

Travel

Travel(mm)(X-Y-Z(Opt.)) - 3200-1600-762(1016)

ATC

Tool Magazine Capacity (Opt.)(T) - 32 (40 / 60 / 120)

SPECIFICATION

NDC3016B

Unit

Values

Spindle Speed (Opt.)

Rpm

GB: 6,000 (IDD: 10,000)

Spindle Power (Opt.)

KW

35 (45)

Spindle Taper (Opt.)

BBT50

X-Axis Travel

Mm

3,200

Y-Axis Travel

Mm

1,600

Z-Axis Travel(Opt.)

Mm

762(1,016)

Distance Between Spindle Nose & Table Top

Mm

200~962 [30"Standard] (450~1212) [30"Raised 250] (200~1216) [40"Raised 250]

Distance Between Columns

Mm

1,800

Table Size

Mm

3,000 X 1,500

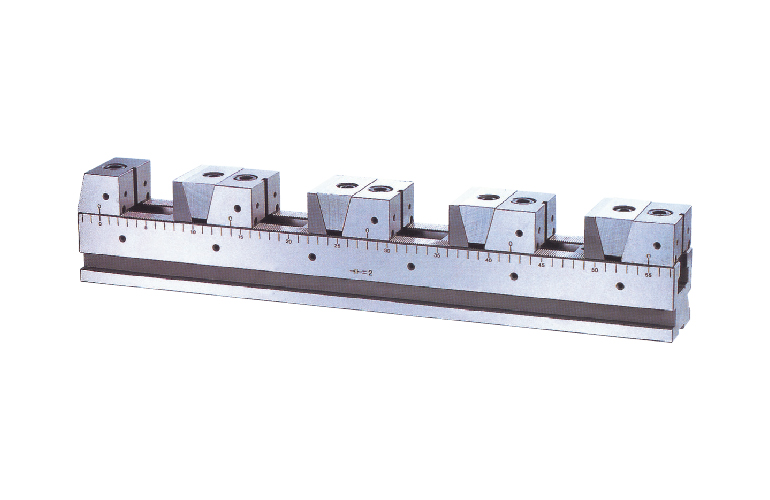

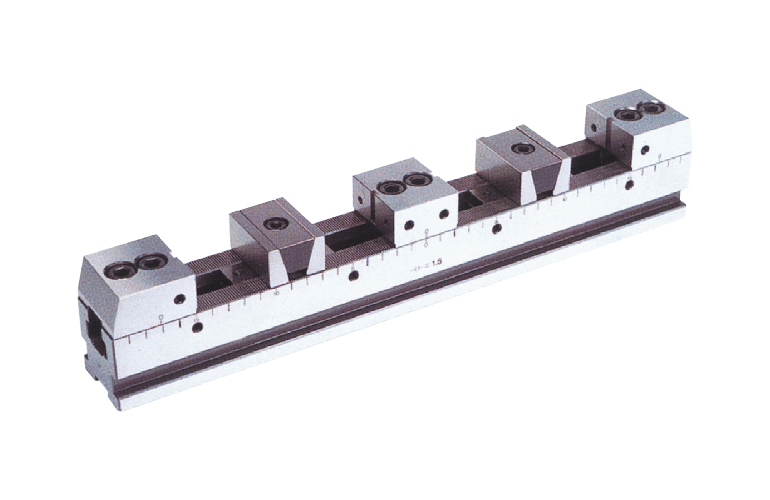

No. T-Slot X Size X Pitch

Mm

8 X 22 X 180

Max. Load On Table

Kg

10,000

X/Y/Z Rapid Feedrate

M/min.

20 / 20 / 15

Cutting Feedrate

Mm/min.

1~10,000

Tool Magazine Capacity (Opt.)

T

32 (40 / 60 / 120)

Tool Weight

Kg/pc

20

Max. Tool Dimension (W/O Adjacent Tools)

Mm

ø125 X 350(ø240 X 350)

Machine Weight

Kg

26,000