DDM5020

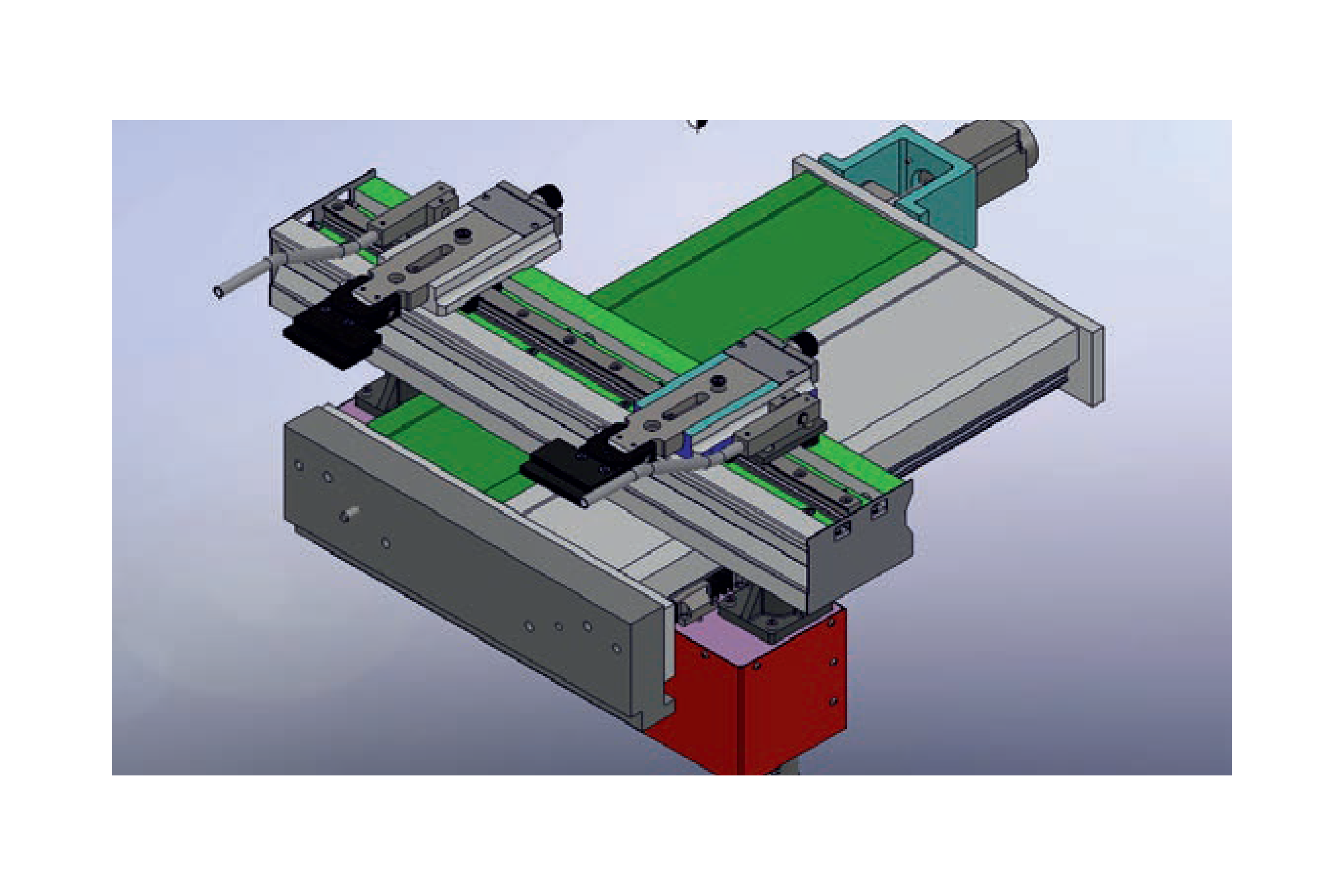

Dener Electric Press Brake Machine DDM5020

Introducing Dener CNC Servo Electric Press Brakes: The Next-gen Bending Machines. Hydraulic-free, They Offer Flexibility, Reliability, And Advanced Capabilities. Eco-friendly, They Minimize Energy Consumption And Maintenance. Experience The Future Of Bending With Dener.

Bending Length(mm)

2040

Bending Capacity(Ton)

50

Dimension(mm)

3170x2260x2500

SPECIFICATION

DDM5020

Unit

Values

Bending Length

Mm

5020

Pressure Force

Ton

50

Max.Stroke

Mm

300

Q-Distance Between Tables

Mm

590

Approaching Speed

Mm/sec

150

Bending Speed

Mm/sec

20

Return Speed

Mm/sec

150

Main Motor Power

KW

11

Dimension

Mm

3170x2260x2500

Machine Weight

Kg

3170

Control Unit

- ESA S 640 Control Unit

- 15" color touch screen

- Automatic bend sequence

- Easy programmable 2D graphic display

- Multiple language options.

- 2D Simulation.

- Remote access.

- ESA 875 W Control Unit (Optional)

Control Unit

- ESA S 640 Control Unit

- 15" color touch screen

- Automatic bend sequence

- Easy programmable 2D graphic display

- Multiple language options.

- 2D Simulation.

- Remote access.

- ESA 875 W Control Unit (Optional)

Work Table

Foldable and height adjustable ergonomic working table makes bending easier and comfortable

Clamping & Tools

Euro Type punch and die ciamping systems Wila mechanical and hydraulic clamping system (Optional)

Clamping & Tools

Euro Type punch and die ciamping systems Wila mechanical and hydraulic clamping system (Optional)

Back Guage

- 2 axis back gauge handles complex parts with ease (5 axis optional ⁃ Z1, Z2 and X-Prime with ESA660 controller)

- High speed movement combined with high accuracy drives ensures the back gauge is positioned quickly and precisely every time for the operator

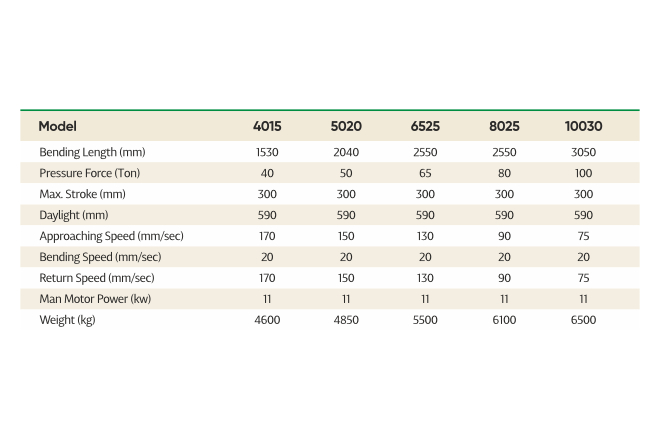

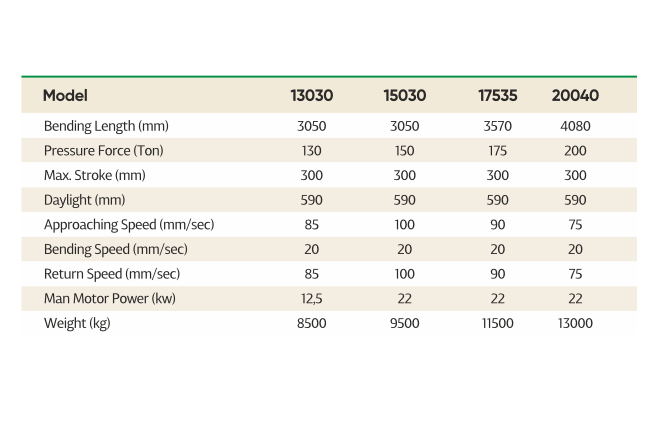

Specifications

Specifications

Specifications