CAMDER 3.6 GS

WIM Deep Hole Drilling Machine CAMDER 3.6 GS

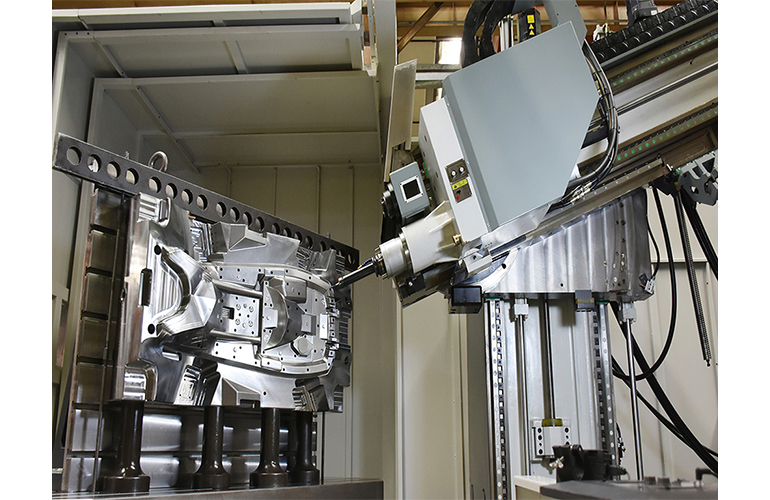

WIM Deep-hole Drilling Machines Accurately Produce Deep Holes In Materials Using High-pressure Coolants And Long Drills. CAMDER Drilling Machines Are 6-axis Coordinated Advanced Drilling-milling Machines.

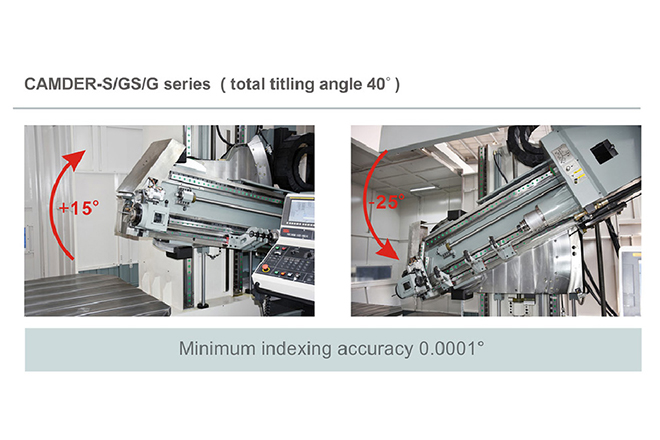

Total Tilting Angle

40°

Minimum Indexing Accuracy

0.0001°

Max. Load Capacity (ton)

8-30

SPECIFICATION

CAMDER 3.6 GS

Unit

Values

Gun Drill Machining Hole Diameter

Mm

3-50

Ejector Drill Machining Hole Diameter

Mm

18-65

Maximum Drilling Depth In Gun Drill Operation

Mm

1500+550

Maximum Drilling Depth In Ejector Drill Operation

Mm

1000

Tapping Capacity

M36 X 4

Milling Capacity

Cc/min

400

Table Horizontal (X)

Mm

3000

Ram Travel (Y)

Mm

1500

Column Horizontal Travel (Z)

Mm

800

Ram Tilting Angle (A)

Clockwise15°, Counterclockwise25°

Spindle Center To Table Top

Mm

0-1500

Distance From Table Center To Spindle Nose

Mm

630-1430

Spindle Bore Taper

BT 50

Max Spindle Speed

Rpm

4000

X/Y/Z/W Rapid Traverse Rate

M/min

8

Ram Maximum Tilting Speed (A)

Degree/min

215

Table Maximum Rotation Speed (B)

Rpm

2

Spindle Motor

15/18.5 KW (15min)

X Axis Servo Motor

N.m

36

Y Axis Servo Motor

N.m

27

Z Axis Servo Motor

N.m

27

W Axis Servo Motor

N.m

27

A Axis Servo Motor

N.m

27

B Axis Servo Motor

N.m

36

Total Power Requirement

KW

64

Max. Load Capacity

Ton

30

Size (Length X Width)

Mm

2400 X 1800

Coolant Pressure (gun Drill)

MPa

2-11

Coolant Pressure (ejector Drill)

MPa

1.0-2.0

Rate Of Flow (gun Drill)

L/min

6-140

Rate Of Flow (ejector Drill)

L/min

40-163

Floor Space Require (Length X Width)

Mm

9390 X 7880

Machine Height

Mm

4580

Machine Weight

Ton

40

CNC System

FANUC IO-MF PLUS

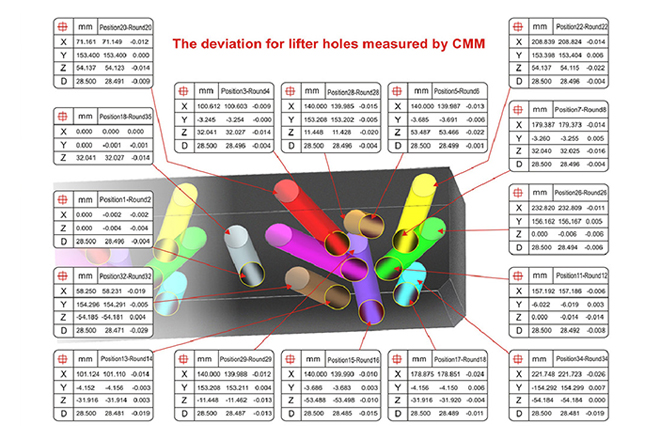

Lifter Hole Position and Diameter Deviations

Lifter Hole Position and Diameter Deviations

Total Tilting Angle