Every die, mold, or precision component begins with one goal - to achieve accuracy, precision, and superior surface finish, even on the hardest materials. Traditional machining methods often struggle to handle complex shapes, sharp corners, and deep cavities. That’s where Electrical Discharge Machining (EDM) stands out.

Manufacturers who need to machine hardened materials with intricate geometry rely on Die Sinking EDM. It removes material through controlled electrical sparks between an electrode and a workpiece submerged in dielectric fluid, delivering precise and smooth results.

This process has become a key technology across mold making, die casting, and precision tool manufacturing industries.

As the demand for higher accuracy, faster production, and automation grew, EDM technology evolved into a more advanced form - CNC Die Sinking EDM.

In this blog, let’s explore in detail what CNC Die Sinking EDM is, and how it differs in performance between Single Head and Twin Head configurations.

Why CNC Die Sinking EDM Is the Smarter Choice

In CNC Die Sinking EDM, the travel axes are fully automated. Every spark, feed, and movement are precisely controlled through Computer Numerical Control (CNC), ensuring consistent and repeatable results for every part.

Manufacturers choose CNC Die Sinker EDM machines because they:

• Reduce manual effort and setup time.

• Handle complex 3D cavity machining with ease.

• Deliver micron-level accuracy and mirror surface finishes.

• Maintain stable performance.

Types of CNC Die Sinking EDM

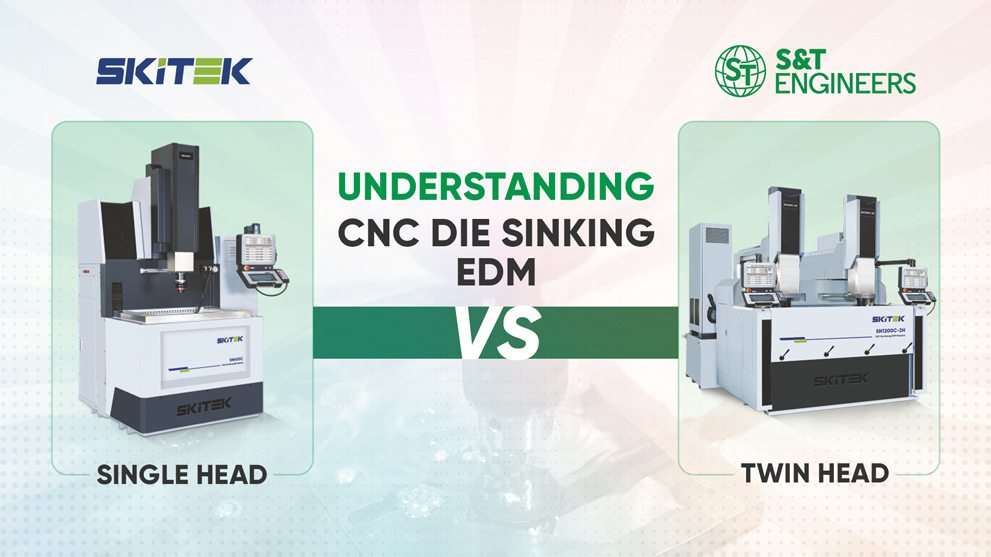

When it comes to CNC Die Sinker EDM machines, there are two main types — Single Head and Twin Head models. Each is engineered for specific production needs. Understanding their differences helps manufacturers choose the right machine for their applications.

Single Head CNC Die Sinking EDM

A Single Head CNC Die Sinker EDM features one electrode head for machining. It’s ideal for precision toolrooms, small batch production, and complex mold making where accuracy is the top priority.

Key Benefits:

• Perfect for high-precision, low-volume applications

• Simplifies setup and operation

• Cost-effective solution for small and medium-scale manufacturers

• Ensures excellent surface finish and dimensional accuracy

Single head machines are commonly used in mold manufacturing and die casting component machining, where part geometry and surface finish are critical.

Twin Head CNC Die Sinking EDM

A Twin Head CNC Die Sinker EDM features two independently controlled electrode heads, enabling machining on the same or different workpieces simultaneously. This setup reduces idle time and doubles productivity, making it perfect for high-volume production.

Key Benefits:

• Two heads double the productivity

• Ideal for large dies, molds, or multiple cavity machining

• Reduces cycle time significantly

• Offers flexibility – both heads can work independently or in sync on one part

Twin head EDMs are widely used in automotive, aerospace, and large-scale die and mold industries, where efficiency and precision are crucial.

Single Head vs Twin Head — Choose the right CNC Die Sinking EDM for you

This is completely depending on your production goals.

Ready for purchasing?