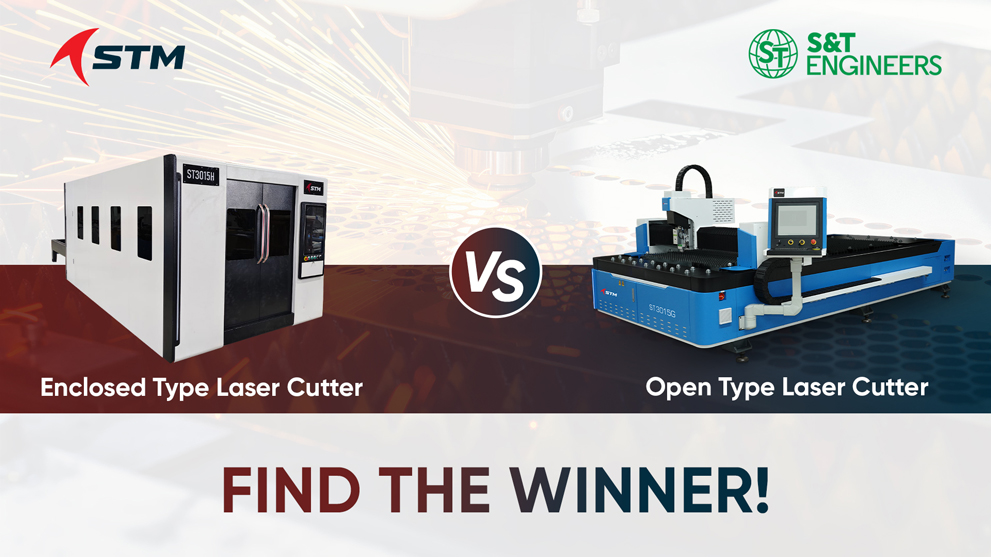

Open vs. Enclosed: Which CNC Laser Cutting Machine is Right for You?

Choosing a CNC laser cutting machine is a significant decision, whether you operate a small fabrication shop or a large manufacturing facility. As a leading manufacturer of both open and enclosed laser cutting machines, we understand the distinct advantages of each. The right choice depends on your specific needs, focusing on factors such as safety, productivity, and the type of work you handle.

Well break down the key differences to help you make an informed decision.

The Open-Type Laser Cutter: The King of Flexibility

An open-type sheet metal laser cutting machine offers maximum versatility. With no enclosure, you have complete access to the work area, making it easier to load and unload large, oversized, or irregularly shaped materials. The main benefits of this type are flexible handling of materials and ease of use for custom or unique jobs.

Choose an open-type laser cutting machine if you need to:

Handle Custom Jobs: Easily load and unload one-off projects or unique materials, making open-type laser cutting ideal for custom manufacturing needs.

Process Large-Scale Work: Cut oversized metal sheets or structural components that exceed the dimensions of an enclosed machine bed, without constraints.

Stay on Budget: Open systems generally have a lower initial price point, offering an accessible entry into laser cutting for cost-conscious operations.

While an open design offers freedom, it comes with a greater responsibility for safety. Operators must use a dedicated safety zone and wear appropriate protective eyewear to prevent exposure to the powerful laser beam and its reflections.

The Enclosed-Type Laser Cutter: The Champion of Safety and Speed

If safety and high-volume production matter most, the enclosed-type fiber laser cutting machine stands out as the optimal choice. The full housing completely contains the laser beam, sparks, and harmful fumes, protecting operators and maintaining a clean work environment. This is a crucial feature for businesses that must meet strict safety and environmental regulations.

Choose an CNC enclosed-type laser cutting machine if you need to:

Maximize Productivity: Enclosed-type CNC laser cutting machines with double pallets are designed to deliver continuous operation. You can cut and load simultaneously, which means while one sheet is being cut, you can unload the finished part and load the next sheet. This process virtually eliminates downtime and ensures maximum productivity for your manufacturing operations.

Prioritize Safety: The full enclosure, safety interlocks, and integrated fume extraction systems make enclosed-type laser cutting machines one of the safest options available for your workshop.

Cut Hazardous Materials Safely: If your materials produce toxic fumes or dust, a sealed environment with a powerful filtration system is essential. This ensures safe operation while maintaining a clean and healthy workspace.

The enclosed design also provides a controlled environment, protecting the cutting process from external dust and contaminants. This ensures more consistent and higher-quality cuts. The sound-dampening enclosure also contributes to a quieter workspace.

Open vs. Enclosed Laser Cutting Machines: How to Decide? Making the Right Choice for Your Business

The decision between an open and enclosed machine often comes down to this core question: Are you prioritizing flexibility or productivity?

If your projects are diverse, frequently require handling large or unique materials, and budget is a key consideration, an open-type machine may be the most suitable option.

If your business is expanding, you are focused on increasing output, and require the highest standards of safety and consistency, investing in an enclosed-type machine offers long-term value.

Both types of machines deliver the precision and speed of laser cutting. Looking for the right CNC laser cutting solution? Whether open or enclosed, S&T Engineers help you choose the best machine for your production needs. Get a free consultation today. Explore our STM Laser Cutting Machines for high-volume production.