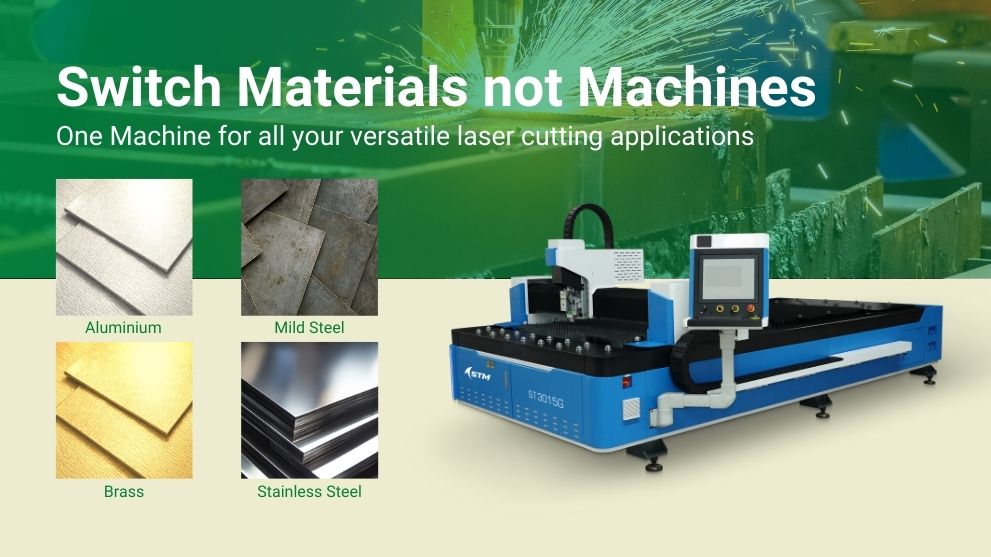

Need to Cut Different Materials Every Day? Fiber Laser Cutting Machines are Built for Versatility

Manufacturing and metal fabrication industry move fast today, so being versatile isn’t beneficial — it’s essential. Sheet metal fabricators and OEMs cut different metals every day. But one question always comes up: Can one machine really handle cutting multiple types of metals efficiently and accurately?

Traditional cutting technologies often struggle with different materials. That means higher costs, more delays, and the hassle of running multiple machines. Fortunately, Fiber laser cutting machines offer a powerful solution designed precisely for this challenge.

What is a Fiber Laser Cutting Machine?

A fiber laser cutting machine uses powerful fiber optic-generated laser beams to cut through metal and other materials with incredible precision. It focuses intense energy on a small point, instantly melting or vaporizing the material. This allows for clean, fast, and highly accurate cuts in modern manufacturing.

The Problem: Multiple Materials, Multiple Machines?

Most fabrication shops work with a range of metals — from mild steel to stainless steel, aluminium, brass, and sometimes copper. Each metal has unique properties: hardness, reflectivity, melting point, and thickness requirements. Using separate machines for each material type means:

- Increased capital expenditure on different cutting equipment.

- Complex scheduling and workflow management.

- Higher maintenance and training costs for multiple systems.

- Longer production cycles due to machine changeovers.

The question is, can one machine really cut all these materials without compromising on speed or quality?

The Solution: Fiber Laser Cutting Machines for Multi-Material Cutting

Fiber laser cutting technology has emerged as the industry’s go-to solution for multi-material cutting. Unlike conventional CO₂ laser machines or plasma cutters, fiber lasers utilize a solid-state laser source that generates a highly focused beam through optical fibers. This unique design offers several advantages:

- Exceptional beam quality that remains consistent across different metals.

- High absorption rates on reflective and non-reflective metals alike.

- Flexibility to cut a wide range of thicknesses and materials with minimal setup changes.

How Fiber Lasers Handle Different Metals

- Mild Steel & Stainless Steel: Fiber laser cutting machines cut these metals cleanly and quickly, producing precise edges with minimal finishing.

- Aluminium: Fiber lasers handle reflective and heat-conductive aluminium smoothly.

- Brass: These reflective metals are challenging for other lasers, but fiber laser cutting machines equipped with anti-reflective features cut them safely without damage.

| Material | Reflectivity | Thermal Conductivity | Typical Laser Power Recommendation |

| Mild Steel | Low | Medium | Moderate Power (2–6 kW) |

| Stainless Steel | Medium | Low to Medium | Moderate to High Power (3–8 kW) |

| Aluminium | High | High | Higher Power (4–12 kW) |

| Brass & Copper | Very High | High | High Power with Anti-reflective Features (6–12 kW) |

Benefits of Versatility in Your Production Line

- One machine for multiple materials reduces equipment costs.

- Faster job turnaround by minimizing machine changeovers.

- Consistent, high-quality cuts across all metals.

- Lower power consumption and maintenance compared to other cutting technologies.

Why Choose STM Fiber Laser Cutting Machines?

At S&T Engineers, our STM fiber laser cutting machine, is engineered for multi-material versatility and industrial-grade reliability. Whether you’re processing thin aluminium sheets, mild steel, brass, or thick stainless-steel plates, our laser cutting machines deliver exceptional performance every time.

Our solutions include:

- Advanced CNC controls for precision and ease of operation.

- Optional automation features for loading, unloading, and nesting.

- Comprehensive support from installation to training and maintenance.

Ready to streamline your metal cutting operations with one machine that does it all?

Contact S&T Engineers today for a personalized consultation and get the STM fiber laser cutting machine price. Discover how our STM fiber laser cutting machine, can transform your production line, maximizing efficiency and cutting costs across all your materials.