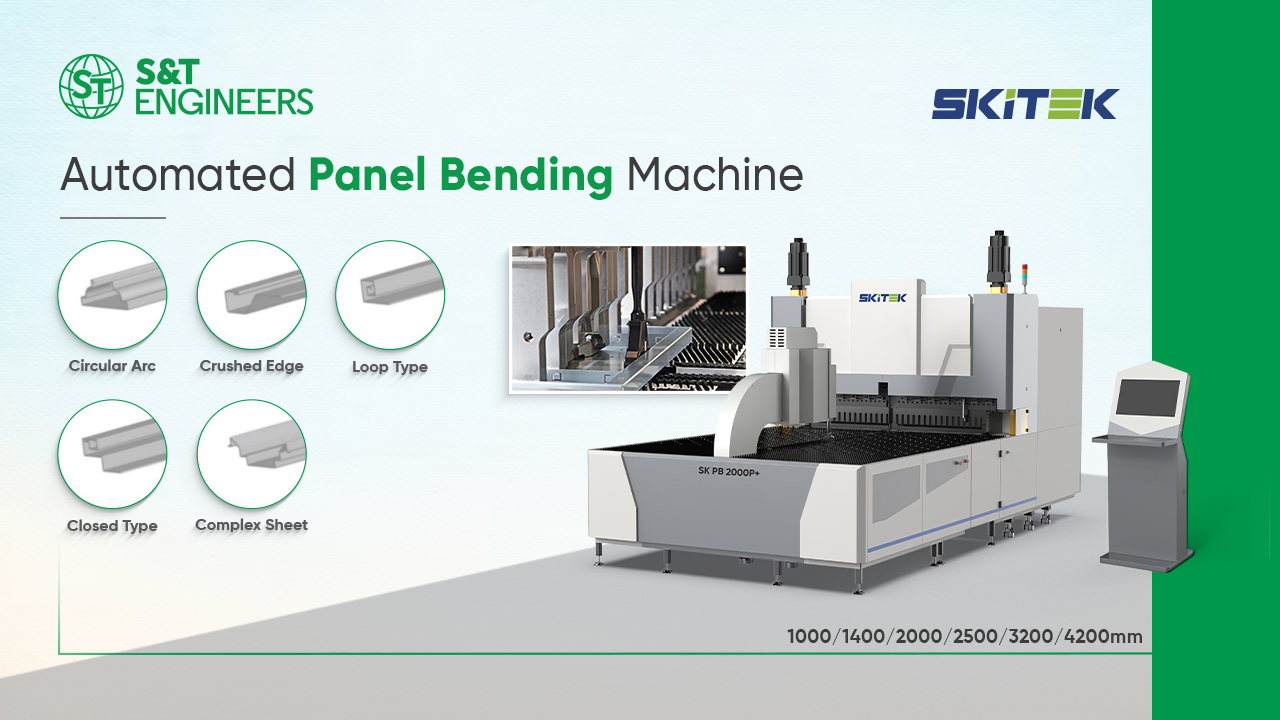

SKITEK Automated

Panel Bending Machines: Revolutionizing Sheet Metal Fabrication

In the

world of modern manufacturing, automated panel bending machines represent a

significant leap forward in sheet metal fabrication. These machines, such as

the SKITEK SK PB 2000P+, are not just tools but transformative technologies

that redefine precision, efficiency, and versatility in bending sheet metal.

The

Evolution of Precision and Efficiency

Gone are

the days of manual bending with its inherent variability. Automated panel

bending machines excel in achieving high precision, capable of bending sheet

metal into precise shapes with accuracy measured in thousandths of an inch.

This level of precision is crucial in industries like automotive, electronics,

and appliance manufacturing, where consistency and quality are paramount.

Unleashing

Automation for Consistency

What sets

these machines apart is their automation prowess. They reduce reliance on

manual labor by storing bending programs electronically and executing bends

with robotic precision. This not only ensures consistent, accurate results but

also boosts production efficiency significantly. Compared to manual methods,

automated machines like the SKITEK SK PB 2000P+ can handle complex bends at a

fraction of the time, making them indispensable in high-volume manufacturing

environments.

Applications

Across Industries

The

versatility of automated panel bending machines extends across various

industries. In automotive manufacturing, these machines fabricate car body

components with intricate bends.

- Automotive: Produces car body

components with precise bends.

- Appliance

Manufacturing:

Fabricates parts for appliances requiring intricate bends.

- Electronics: Manufactures

enclosures for electronic devices with strict quality standards.

- Kitchen Industry : Cabinet Doors, Drawer

Sides, Shelves & Kick Plates, Manufactures

panels with consistent folded edges, enhancing durability and aesthetics.

- HVAC: Shapes sheet metal

ducts efficiently for heating and cooling systems.

Furniture and Construction: Creates components for furniture and architectural applications.

Introducing

the SKITEK SK PB 2000P+: Setting New Standards

At the

forefront of this revolution is the SKITEK SK PB 2000P+, engineered by S&T

Engineers to meet the exacting demands of modern sheet metal fabrication. This

machine boasts advanced features tailored for manufacturing high-quality

kitchen components:

- Box Height Capability: Handles panels up to

300 mm in height, accommodating a wide range of kitchen component sizes.

- Precision in Thin

Materials:

Starts bending from a delicate 0.35 mm thickness, ideal for intricate

designs and lightweight materials.

- Powerful Motor: Equipped with a robust

motor ranging from 25 to 103 kW, ensuring consistent performance across

perse production needs.

- Advanced Automation: Incorporates

state-of-the-art automation for up to 5x faster loading and unloading

cycles, optimizing workflow and reducing setup times.

- User-friendly

Interface:

Simplifies programming and operation, making it accessible even for

operators new to automated machinery.

The SKITEKSK PB 2000P+ represents more than just a machine; its a testament to

innovation in sheet metal fabrication. With its blend of precision, automation,

and efficiency, it sets a new standard for manufacturing excellence. Whether

youre in automotive, electronics, or kitchen manufacturing, this machine is

poised to elevate your production capabilities and meet the challenges of

todays competitive market.